Focus On RoboticPolishingGrindingDeburring System Integration

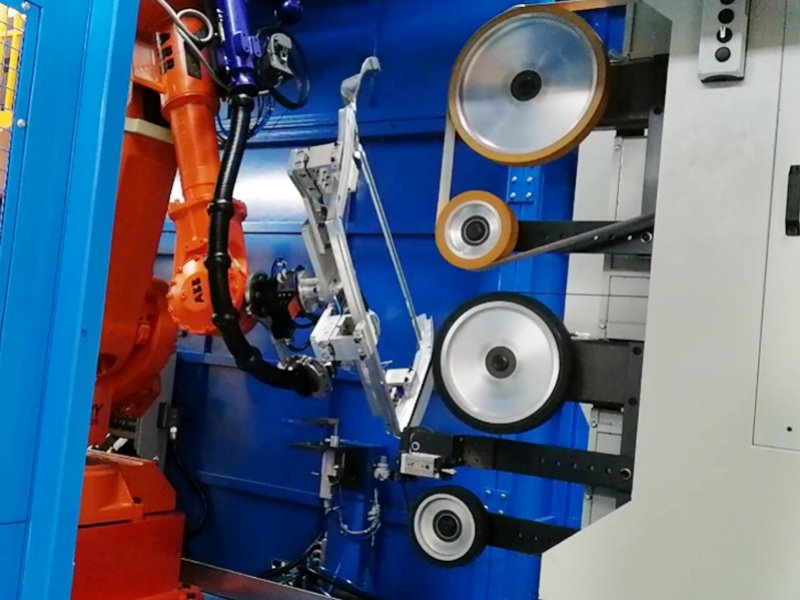

Founded in 2010, Kingstone Robot is a high-tech enterprise which focuses on researching and developing of software and hardware systems for robotic grinding & polishing system and provides turnkey solutions for customers.

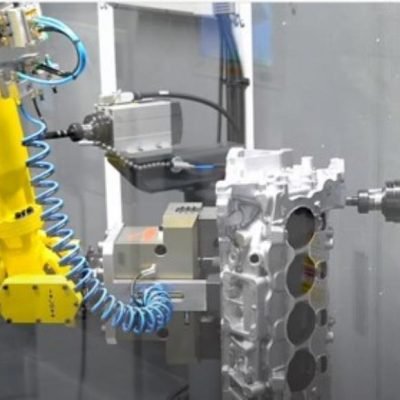

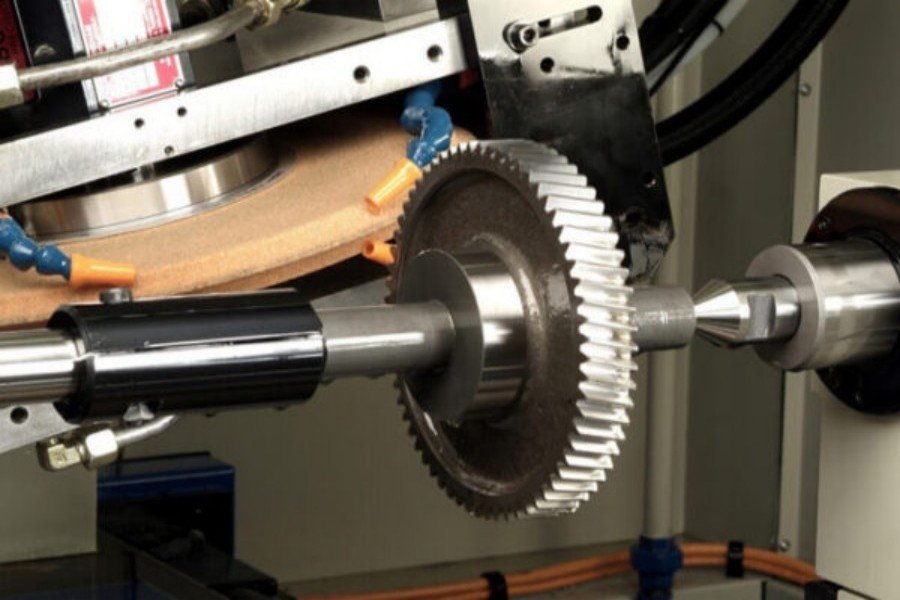

Robotic Grinding

Automated belt-grinding for castings, forgings, and profiles.

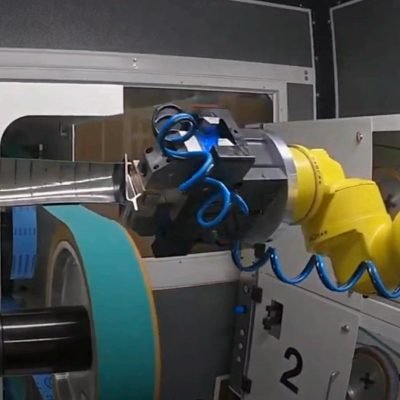

Robotic Grinding Polishing

Multi-head polishing for stainless steel and aluminum parts.

Robotic Buffing

Cloth-wheel buffing for smooth and glossy finishes.

Robotic Complex Unit

Combined polishing and buffing for curved or detailed parts.

About Kingstone Robotics Solution

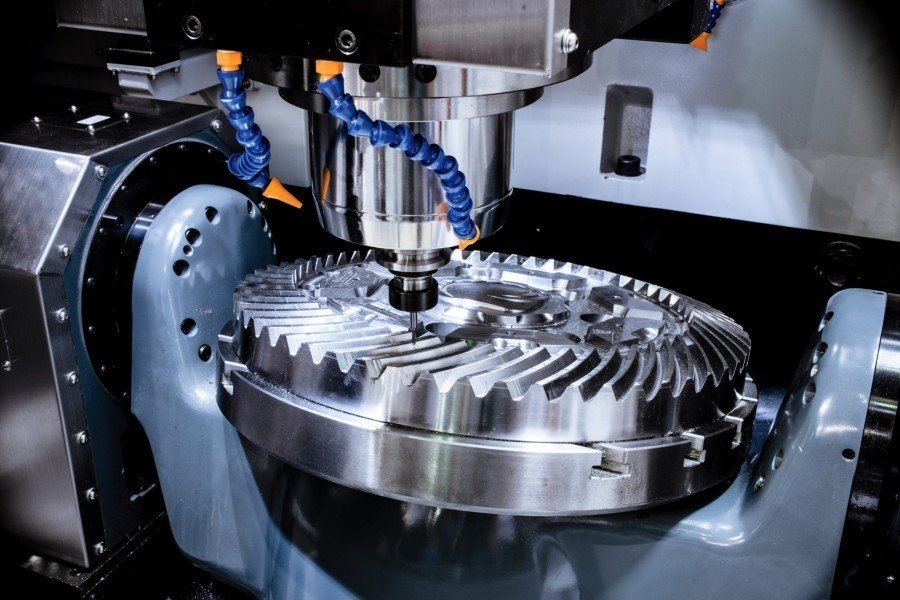

Robotic Grinding, Polishing & Deburring—Engineered for Perfect Surfaces

At Kingstone Robotics, we design compact, modular stations that drop into your line in weeks—not months. Whether you’re chasing mirror finishes on faucets or burr-free castings for drivetrains, our team tunes every detail around your parts and takt time.

Supports ABB / FANUC / KUKA robots (10–60KG payload range)

Floating-force control & auto compensation for uniform finish

Dust-proof, noise-insulated enclosures for safe, clean operation

Tool quick-change & offline programming for rapid product switching

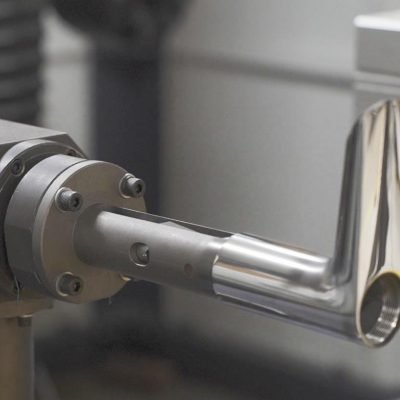

Robotic Deburring

High-speed tools erase flashes and parting lines while preserving tight tolerances.

What We Do

The Best Quality of Robotic Manufacturing

Zhejiang Kingstone Robot & Technology Co., Ltd. is a leading manufacturer of robotic polishing, grinding, and deburring machines, specializing in the development of fully automated surface finishing solutions. At KS Robotics, we deliver robotic automation for grinding, polishing, and deburring, transforming tedious manual work into a seamless, intelligent process. Our advanced systems adapt to material variations, optimize efficiency, and ensure precision at scale, empowering manufacturers to stay ahead in an increasingly competitive market.

156+

Employees

2075+

Projects

1862+

Customers

Who We Are

Your End-to-End Partner in Surface Finishing Automation

Explore our core technologies and full-service capabilities to see how we turn your finishing challenges into automated success.

- Flexible for Multiple Materials

- Customer-first process engineering

- Surface quality that meets global standards

- In-House R&D & System Integration

- Full Lifecycle Support

Our Services

Why Choose Kingstone Robotics?

We provide turnkey robotic systems for polishing, grinding, deburring, and material removal—ready to run without third-party integration. Kingstone Robotics handles the full project lifecycle, from design to installation, ensuring a seamless, efficient solution tailored to your production needs.

Tailored Solutions

We specialize in customizing every solution to fit your specific requirements, ensuring a perfect match for your unique production needs.

Complete Service Coverage

From initial consultation and system design to installation and ongoing support, we manage every aspect of the project to ensure seamless integration.

Proven Track Record

With years of cross-industry experience, Kingstone Robotics has partnered with leading names like ABB, KUKA, FANUC, 3M, and Kawasaki. We’ve successfully delivered projects across 14 application industries, earning long-term trust from global clients.

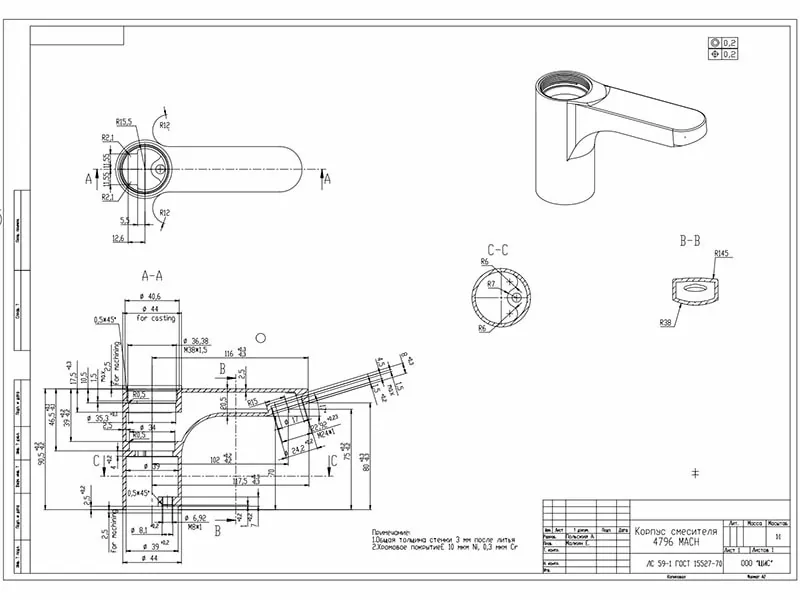

3D Visual Inspection Mode

We utilize advanced 3D visual inspection mode, providing superior surface quality control that spot lasers cannot achieve. This technology enables detailed inspection and enhanced accuracy for every part processed.

Open Parametric Design

Our design process is highly flexible with open parametric design, allowing for easier customization to meet your specific needs. In contrast, traditional systems rely on rigid, single-targeted parameter designs.

Automated Polishing Application

Not Sure lf Kingstone Robotics Can Support Your Needs?

With proven applications across 14+ industries, from automotive to consumer electronics, Kingstone Robotics has successfully addressed a wide range of challenges. Our state-of-the-art robotic systems are designed to meet the most complex production needs, ensuring higher precision, efficiency, and profitability.

Complete Custom Automation Polishing Solution From A to Z

Step 1: Requirement & Design

We analyze your product, material, and finishing goals to create a tailored automation plan.

Step 2: System Integration & Assembly

Robots, grinding units, and controls are configured, tested, and assembled into a complete turnkey solution.

Step 3: Installation & Launch

On-site installation, operator training, and system calibration ensure smooth production start-up.

Testimonial

We Are Trusted By Customers from Over 14+ Industry

From automotive casting to faucet polishing, our robotic systems are delivering value in real production lines every day.

Head of Production, Nordic Foundry Group (Denmark)Entrepreneur

“The four-station polishing unit brought incredible shine and uniformity to our bathroom fittings. The integration was smooth, and they delivered on time—even during peak season.”

Procurement Manager, ChromeLux Hardware (France)

“Our aluminum frame grinding was a bottleneck until Kingstone’s automated solution went live. Now it runs 24/7 with minimal operator touch. Highly recommended.”

Operations Director, Pacific E-Bike Components (Taiwan)

“Kingstone’s robotic grinding system helped us cut labor by 60% and improved our part consistency dramatically. Their team understood our casting process better than some of our own engineers.”