Automated Polishing Technology

Advanced Robotic Finishing Technologies

Kingstone Robotics delivers expert automation across simple to highly complex surface finishing tasks.

- Entry-Level Applications: Faucet grinding, door handle polishing, wheel hub deburring

- Complex Surfaces: Automotive parts, engine casings, gearbox components with irregular geometries

- Large & High-Precision Workpieces: Car rear bilge structures, stainless steel sink basins, and curved sheet metal

What Sets Us Apart:

We specialize in robotic grinding, polishing, and deburring of components that are large, curved, or geometrically irregular—tasks that most integrators find difficult to automate reliably. Our systems maintain high consistency, ±0.01mm accuracy, and work under variable force control for curved surface transitions.

Full-Process Automation Engineering

Our technology goes beyond hardware—it’s about delivering a fully thought-through system ready for production.

Every Kingstone solution is a result of detailed process planning. From digital twins to simulation-based tool paths, we ensure each automation cell is designed to reduce operator intervention, improve yield, and maximize uptime.

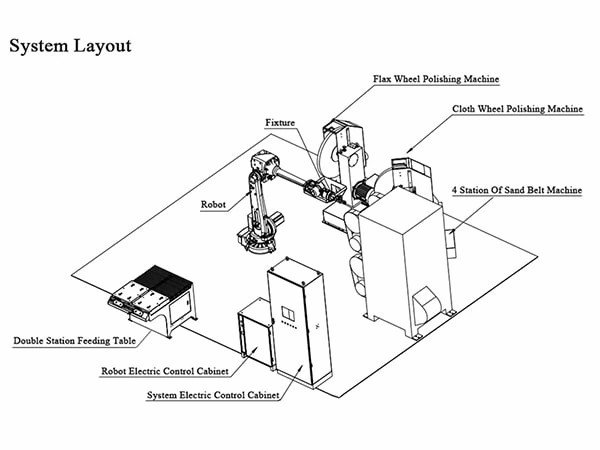

Custom fixture and tool design,3D modeling of workpieces,Equipment layout and workflow simulation

Factory floor planning with 3D footprint diagrams,Process schematics for each grinding/polishing step

About Kinestone Robotics

Surface Finishing Service

- Robotic Grinding Machine

- Robotic Grinding Polishing Machine

- Robotic Deburring Machine

- Robotic Buffing Machine

- Robotic Complex Unit

- CNC Polish Machine

Continuous R&D and Integration Expertise

We continuously develop robotic grinding and polishing systems tailored to evolving industry needs. Kingstone aims to become a top-tier system integrator by offering not just equipment, but smart, production-ready solutions that fit each customer’s real manufacturing environment.

How Kingstone Robotics Redefines Industrial Surface Finishing

In today’s precision-driven manufacturing landscape, robotic surface finishing systems must go beyond automation — they must be intelligent, adaptable, and data-validated. Kingstone Robotics delivers on that demand with an upgraded system architecture that outperforms traditional robot grinding solutions.

Kingstone Robotics Upgraded Systems

Engineered for industrial consistency, flexibility, and process control:

Closed-Loop Programming

Real-time feedback enables precise control of grinding force, speed, and path, ensuring stable output quality.3D Visual Inspection Mode

Full-surface contour scanning enables dynamic adjustment, ideal for irregular or multi-angled parts.Open Parametric Design

Supports multi-dimensional process configuration—force, direction, contact area, speed, etc.—based on workpiece characteristics.Standard Consumables Process Database

Data-driven consumable selection ensures repeatability, cost-efficiency, and optimal surface.

Traditional Systems (Others)

Limitations commonly found in the industry:

Open-loop Programming

Programs run without real-time feedback, leading to inconsistencies in surface finish.

Spot Laser Detection

Only point-based detection; unable to handle complex surfaces with dynamic feedback.

Single-Target Parameter Design

Parameters are fixed for a specific scenario, reducing adaptability to mixed materials or varied part geometries.

Empirical Consumables Selection

Relies on operator experience; results vary and lack repeatability.

Why It Matters

Traditional open-loop systems lack the adaptability to respond to real-time variations, often resulting in inconsistent finishes. Kingstone’s closed-loop control systems utilize real-time feedback to adjust grinding force and tool paths dynamically, ensuring uniform surface quality across all components. This approach minimizes defects and reduces the need for rework, leading to significant cost savings and improved product quality.

Standard 2D inspection methods fall short in detecting subtle surface irregularities, especially on complex geometries. Kingstone employs advanced 3D vision systems that capture detailed surface profiles, enabling precise detection of imperfections and ensuring consistent quality. This technology is particularly beneficial for components with intricate designs, such as engine blocks and gearbox housings.

Variability in manual processes can lead to inconsistencies in product quality. Kingstone’s standardized process database ensures that each operation adheres to predefined parameters, maintaining consistency across all production batches. This standardization streamlines operations, reduces training requirements, and facilitates quicker adaptation to new projects or product lines .

01 — Large Casting Grinding System

Core Technologies:

- Automated size and position detection

- Intelligent tool change with consumable management

- Built-in tool library and standardized process database

Enclosed system with chip removal and safety insulation

Key Benefits:

- Eliminates inconsistency in processing oversized workpieces

- Optimizes tooling and consumable costs

- Maintains a stable, controlled grinding environment for uniform results

02 — Small & Medium Casting Grinding System

Core Technologies:

- Automated size and position detection

- Intelligent tool change with consumable management

- Built-in tool library and standardized process database

Enclosed system with chip removal and safety insulation

Key Benefits:

- Eliminates inconsistency in processing oversized workpieces

- Optimizes tooling and consumable costs

- Maintains a stable, controlled grinding environment for uniform results

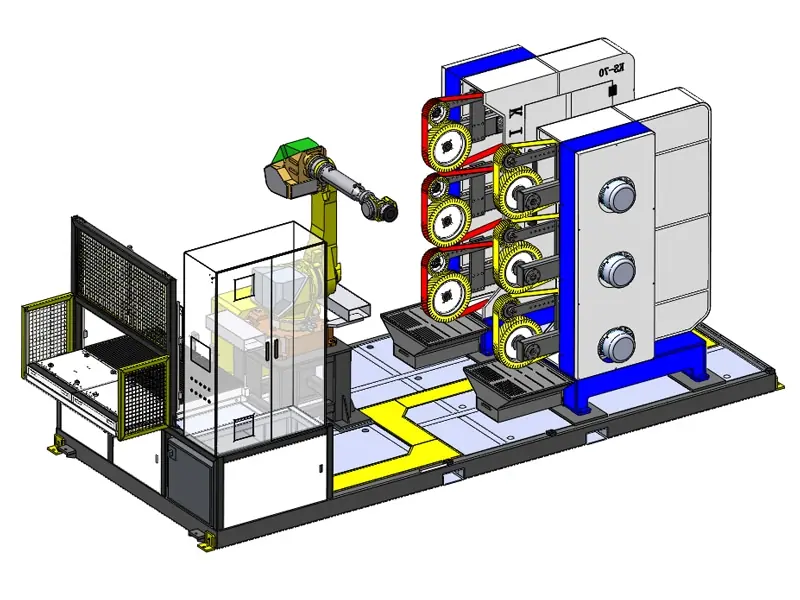

03 — General-Purpose Grinding System

Multi-Station Robotic Solution for Small Parts and High-Volume Finishing

Core Technologies:

- Six-axis industrial robot system

- Dual-station material feeding mechanism

- Multi-position belt sander with force feedback control

- Integrated base frame for structural stability

Key Benefits:

- Boosts production efficiency with continuous dual-station operation

- Delivers consistent surface roughness (Ra) through precision control

- Modular design enables scalable, flexible automation