Newsletter

Request Our Latest Product Catalog

Get detailed specs, applications, and custom options for our robotic polishing, grinding, and deburring systems.

Kingstone Robotics Buffing Unit delivers high-speed, automated surface finishing for intricate parts across automotive, sanitary, and medical industries. Its intelligent control system ensures smooth, uniform buffing on metals and plastics, significantly reducing defects and labor costs. Designed for durability and precision, it boosts productivity with consistent, top-grade polishing results.

Designed for high-efficiency manufacturing, this system integrates automation at every stage—from detection to tool management—to deliver consistent, safe, and low-maintenance operation.

Integration capability with existing equipment for seamless operation.

Organizes multiple tools for automated retrieval and task-specific deployment.

Use advanced vision technology for defect detection and optimized grinding paths.

Provide precise pressure and consistent finishing.

Allow high-volume throughput with minimal manual intervention.

Supports scheduled or condition-based switching of tools and abrasives to reduce downtime.

Detects dimensional deviations and part positioning in real time to ensure processing accuracy.

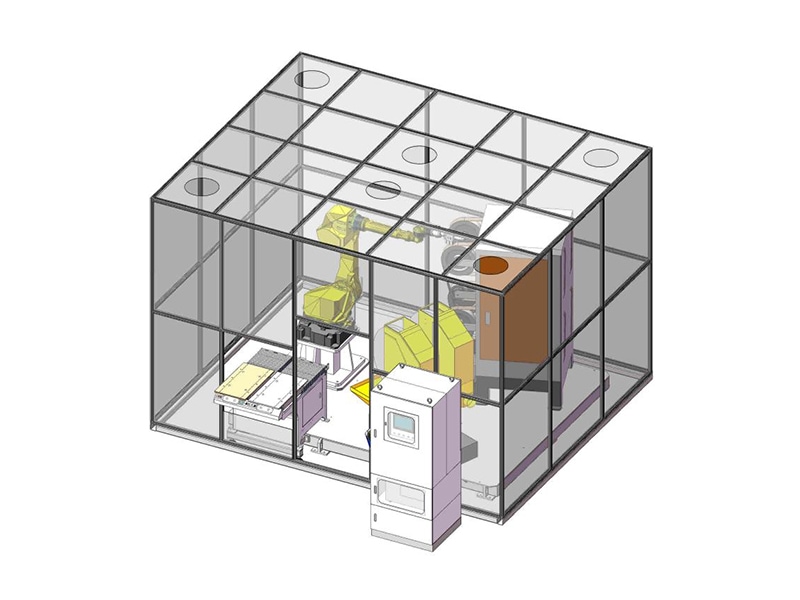

Fully enclosed structure with insulation and safety shielding for operator protection and environmental control.

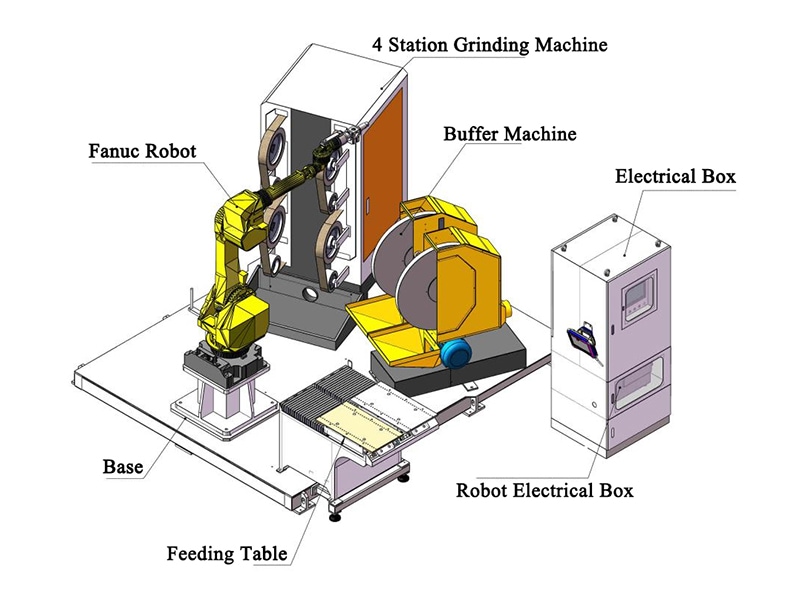

200-2300kg Robot and four station grinding machine and buff machine

Buffing workstations with dustproof house available

Integrated with large buffing workstation

Robotic buffing is an automated finishing process where a robotic arm, equipped with a buffing tool (usually a soft cloth or foam wheel), is used to smooth, polish, and shine the surface of a workpiece. It is the final step in many surface treatment workflows, following grinding and polishing, and is especially critical for parts requiring mirror-like finishes or cosmetic-quality surfaces.

Through adaptive force control and vision-based inspection, the system detects material inconsistencies at an early stage—ensuring stable processing and improved yield.

Kingstone maintains an extensive tool library and customizes robotic grinding media tailored to each customer’s specific process requirements.

With offline programming technology, we enable rapid product deployment and seamless transition between new and existing models—enhancing production flexibility.

Closed-loop control and integrated inspection systems ensure high-precision quality assurance for finished parts, delivering consistent and reliable results.

Our expert team responds to your inquiry within 12 hours, initiating a tailored solution consultation.

We create detailed robotic grinding solutions tailored specifically to your production requirements, ensuring optimal performance and cost-effectiveness.

Our advanced manufacturing facilities ensure your automated grinding system is assembled, calibrated, and tested swiftly to guarantee reliability and accuracy.

We handle complete installation and commissioning at your facility, coupled with comprehensive operator training to ensure smooth integration.

Our commitment extends beyond installation, providing robust after-sales support, spare parts, technical maintenance, and remote assistance to minimize downtime and ensure continuous production.

Superior Product Consistency: Robotic precision drastically reduces defects and ensures consistent quality.

Increased Productivity: Automated operation facilitates 24/7 production, significantly increasing throughput.

Enhanced Workplace Safety: Minimizes worker exposure to harmful dust, noise, and repetitive strain injuries.

Rapid ROI: Automation quickly offsets initial investment costs through labor savings and increased efficiency.

Boost your manufacturing capabilities with cutting-edge robotic grinding solutions. Contact us today for a detailed consultation and discover how we can transform your production process through automation.

Compatible with leading robotic brands: ABB, FANUC, KUKA, Universal Robots.

Force-controlled and vision-guided robotic cells.

Customizable tooling options: sand belts, foam wheels, sanding wheels, rubber wheels.

Multi-axis capabilities for handling complex shapes and intricate surfaces.

Integrated PLC brands including Siemens, Schneider for seamless operations.

From castings to bathroom hardware, we design robotic grinding and polishing systems tailored to your production needs.

Product

Copyright © 2025 Kingstone Robotics. All rights reserved.

Get detailed specs, applications, and custom options for our robotic polishing, grinding, and deburring systems.