Our Service

- Home

- Service

Automated Grinding, Deburring & Polishing Solutions Tailored to Your Needs

Want a flawless finish for your products? Kingstone Robotics offers advanced automation solutions engineered for precision grinding, polishing, sanding, and deburring. Our robots are built for performance across various industries, delivering consistent, high-quality surface results. With deep expertise in robotic finishing, we tailor each system to your specific needs—whether you’re smoothing cast metals or buffing complex parts.

Manual grinding and sanding expose workers to serious safety risks and growing labor shortages. Our robotic systems eliminate these hazards by automating material removal, reducing injuries by up to 85% in grinding operations. Capable of ±0.01mm precision and 24/7 operation, our solutions ensure consistency and speed without fatigue. Whether you’re a small manufacturer or a large enterprise, Kingstone and our certified integrators will work with you to build the right system—boosting product quality, throughput, and workplace safety.

Our Services

Why Choose Kingstone Robotics?

We provide turnkey robotic systems for polishing, grinding, deburring, and material removal—ready to run without third-party integration. Kingstone Robotics handles the full project lifecycle, from design to installation, ensuring a seamless, efficient solution tailored to your production needs.

Tailored Solutions

We specialize in customizing every solution to fit your specific requirements, ensuring a perfect match for your unique production needs.

Complete Service Coverage

From initial consultation and system design to installation and ongoing support, we manage every aspect of the project to ensure seamless integration.

Proven Track Record

With years of cross-industry experience, Kingstone Robotics has partnered with leading names like ABB, KUKA, FANUC, 3M, and Kawasaki. We’ve successfully delivered projects across 14 application industries, earning long-term trust from global clients.

3D Visual Inspection Mode

We utilize advanced 3D visual inspection mode, providing superior surface quality control that spot lasers cannot achieve. This technology enables detailed inspection and enhanced accuracy for every part processed.

Open Parametric Design

Our design process is highly flexible with open parametric design, allowing for easier customization to meet your specific needs. In contrast, traditional systems rely on rigid, single-targeted parameter designs.

Complete Custom Automation Polishing Solution From A to Z

Step 1: Requirement & Design

We analyze your product, material, and finishing goals to create a tailored automation plan.

Step 2: System Integration & Assembly

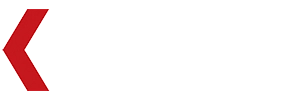

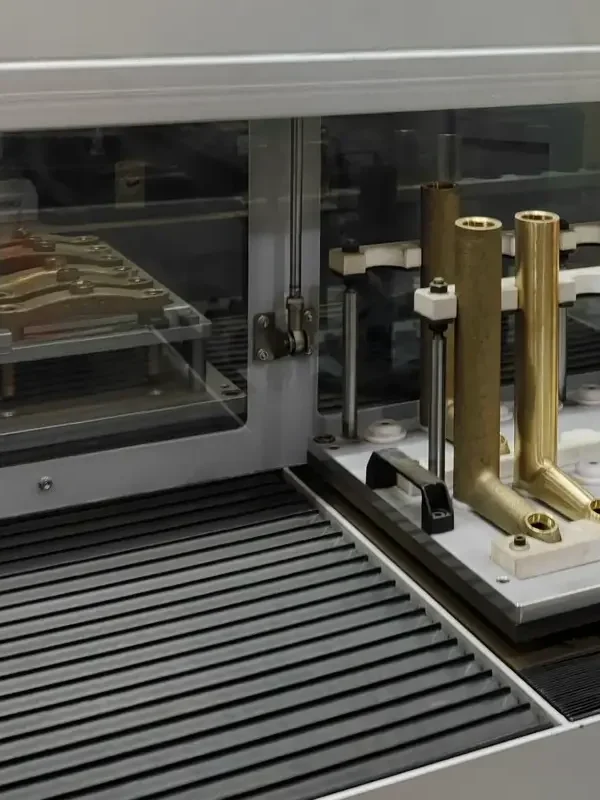

Robots, grinding units, and controls are configured, tested, and assembled into a complete turnkey solution.

Step 3: Installation & Launch

On-site installation, operator training, and system calibration ensure smooth production start-up.

Automated Polishing Application

Not Sure lf Kingstone Robotics Can Support Your Needs?

With proven applications across 14+ industries, from automotive to consumer electronics, Kingstone Robotics has successfully addressed a wide range of challenges. Our state-of-the-art robotic systems are designed to meet the most complex production needs, ensuring higher precision, efficiency, and profitability.

Case Demo

Want To See How It works?

Explore a service process demo and see how we deliver success,step by step.

Customer requirement(Demo)

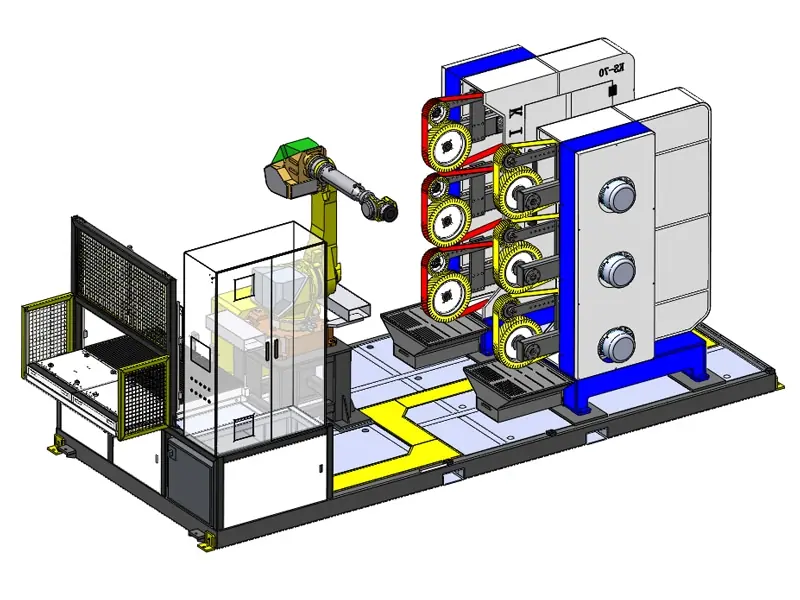

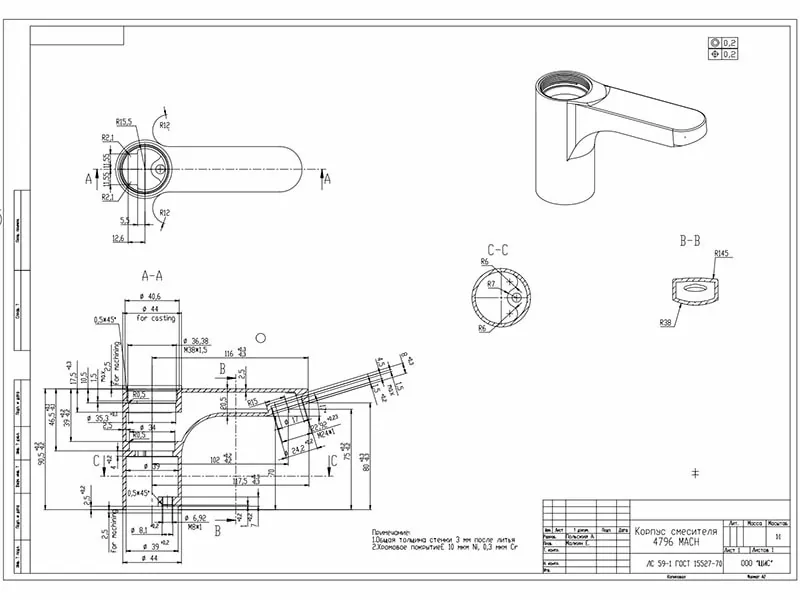

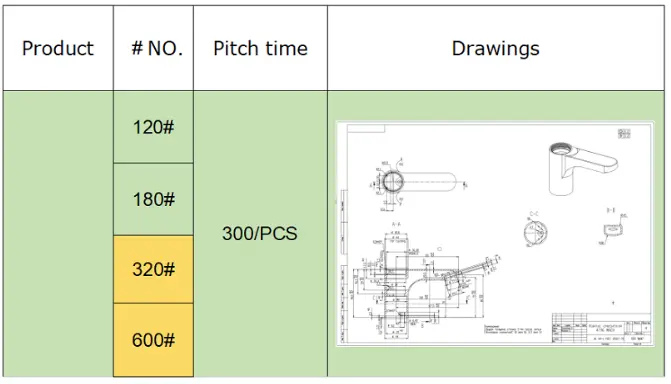

Grinding for products as follows detail:

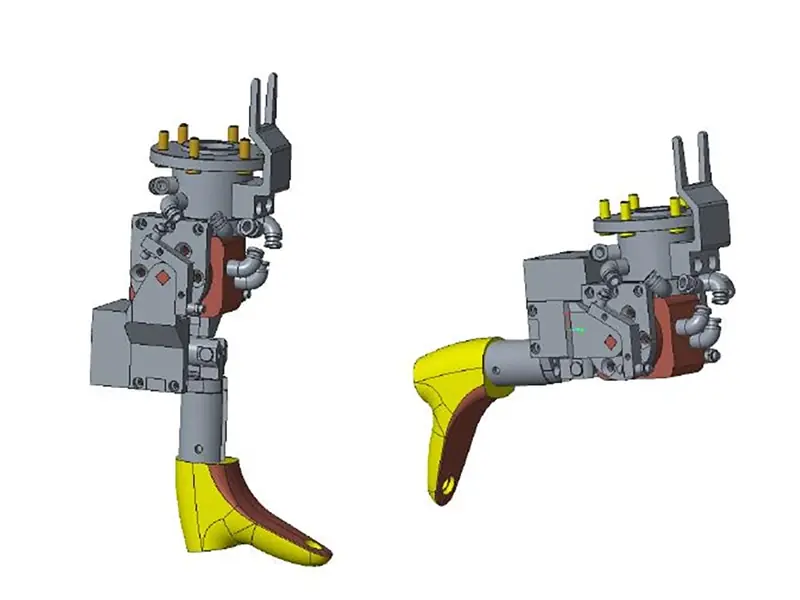

- Product: Faucet & taps

- Grinding process: grinding 120#,180#, 320#, 600# after product peeling machine processing (Material: copper alloy)

- (If the processing effect of the product peeling machine is too poor, it will increase the grinding time)

Quotation List

| System | NO. | Items | QTY | Price(USD) |

| Robot Grinding | 1 | FANUC M-710iC/50E(case demo) | 1 | 50000-180000 |

| 2 | Grinding machine (3 belts each) | 2 | ||

| 3 | Robot base | 1 | ||

| 4 | Double position automatic loading table | 1 | ||

| 5 | PLC flexible polishing system | 1 | ||

| 6 | Gripper & trays | 1 | ||

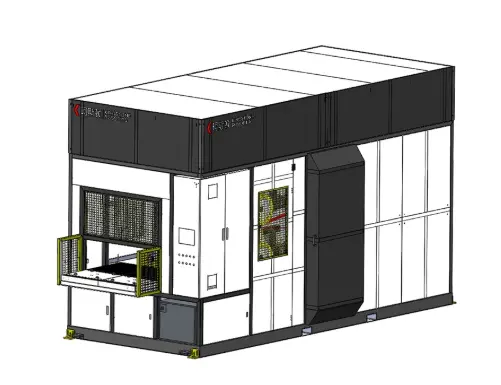

| 7 | Safety room | 1 | ||

| Other | 1 | Programming( Kingstone Robotics can provide a set of procedures for direct production) | 1 | |

| 2 | Electrical design fee | 1 | ||

| 3 | Mechanical design fee | 1 | ||

| Package & transport & declaration | 1 | |||

| 4 | After Service(Kingstone Robotics provides the robot field operation training in the Kingstone Robotics site, and after training can direct operation. | 1 | ||

| Optional Function | 1 | Optional —— Laser detection and correction mechanism | 1 | 20000-40000 |

| 2 | Optional —— Gripper & Tray & Grinding program | 1 | ||

| 3 | Optional —— Cartridge type explosion-proof dust collector | 1 |

Guarantee Period

- Warranty period: one year for mechanical parts and electrical parts, except for human damage.

- The warranty period will take effect after the machine passes the trial.

- The warranty will automatically be voided if any part of the equipment is manipulated or modified by anyone other than KS professional, trained and authorized technicians.

- Any fault or breakdown of the equipment caused by negligence or improper use will not be included in the guarantee.

- The warranty will not cover equipment failure or damage caused by neglect or improper use.

- Kingstone Technology reserves the right to continue to improve our equipment.

- Robot arm guarantee (take ABB as an example, the same applies to others): According to the general conditions stipulated by ABB, the warranty period of the robot arm is 1 year, and any operations related to maintenance or malfunction of the robot are the responsibility of ABB.

- Overseas installation and maintenance service: Engineer installation and commissioning.