3C Electronic

Advanced Grinding Solutions for 3C Electronic Industry Applications

At Kingstone Robotics, our robotic grinding and polishing systems are built to meet the high-precision and aesthetic standards of the 3C electronics industry. Whether it’s aluminum smartphone housings, stainless steel smartwatch frames, or magnesium alloy laptop shells, our systems deliver uniform surface quality across complex geometries and premium materials. Designed to handle fine edge finishing, surface smoothing, and high-gloss polishing, our robotic solutions ensure dimensional consistency, reduce manual labor, and boost production throughput. From enhancing product durability and tactile feel to achieving flawless visual appeal, our automated finishing systems help electronics manufacturers deliver sleek, high-performance consumer devices with reliable, repeatable quality at scale.

Why Surface Finishing Matters in 3C Electronic

- Improves mechanical reliability and structural integrity

Surface finishing strengthens key components in devices like smartphones, laptops, and wearables, reducing the risk of micro-cracks and mechanical failure under daily use and handling. - Enhances corrosion resistance and product lifespan

High-quality finishing protects aluminum, stainless steel, and magnesium alloy housings from oxidation, sweat, and environmental exposure—ensuring devices maintain performance and appearance over time. - Delivers consistent surface quality and premium aesthetics

Precision-polished surfaces meet consumer expectations for sleek, uniform finishes across product lines, supporting brand image and enhancing the tactile and visual appeal of modern electronics.

Challenges of Manual Finishing in 3C Electronic

Labour-Intensive. Inconsistent. Costly.

Manual grinding and polishing of 3C electronic components—such as smartphone frames, laptop shells, or smartwatch casings—is slow, labor-intensive, and challenging to scale for mass production. Achieving precise surface finishes and dimensional accuracy often depends on skilled technicians, yet human fatigue and variability can lead to inconsistent quality and increased defect rates.

Materials commonly used in 3C products—like anodized aluminum, stainless steel, and magnesium alloys—are sensitive to heat and surface pressure, making manual finishing prone to deformation or scratches. These requirements demand fine-tuned control over speed, pressure, and toolpaths—areas where robotic systems excel, offering greater consistency, efficiency, and throughput for modern electronics manufacturing.

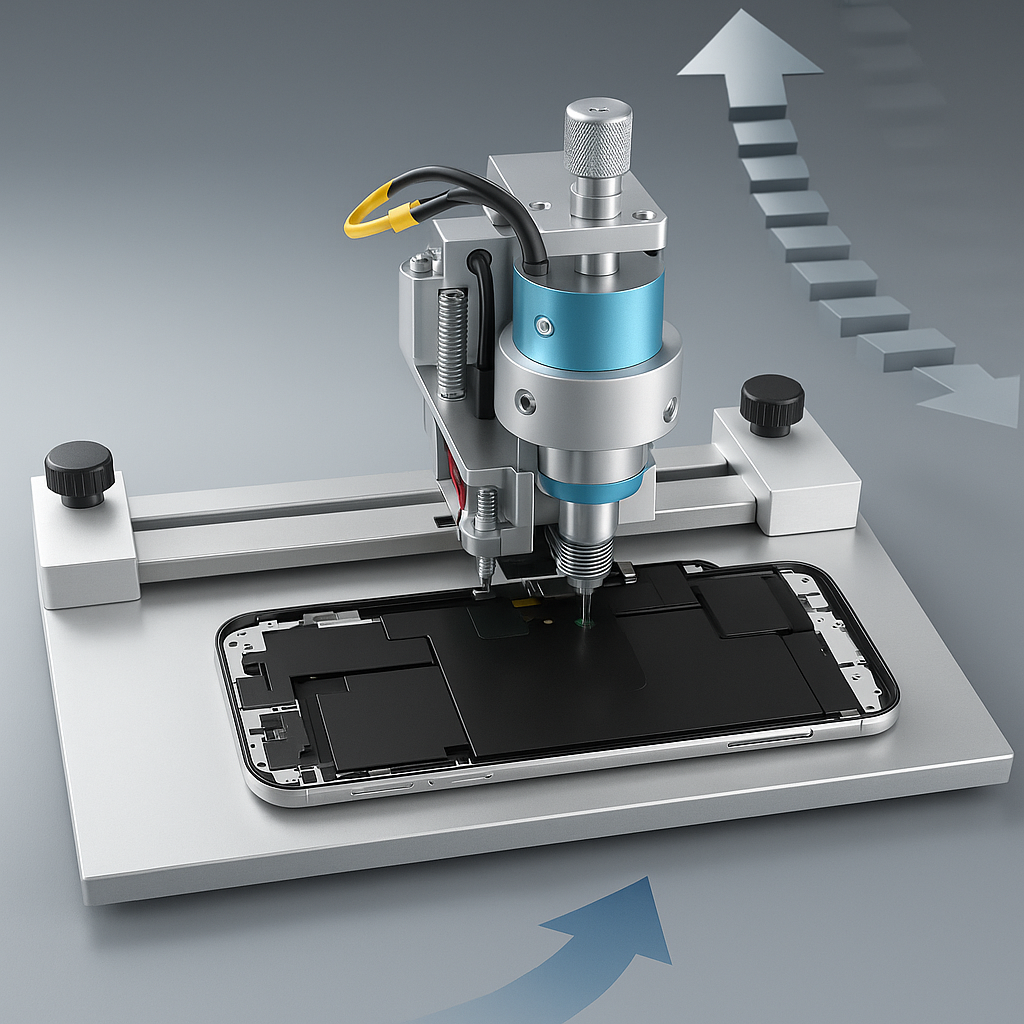

Camera Frame Grinding

Laptop Grinding

Phone Case Polishing

Watch Frame Polishing

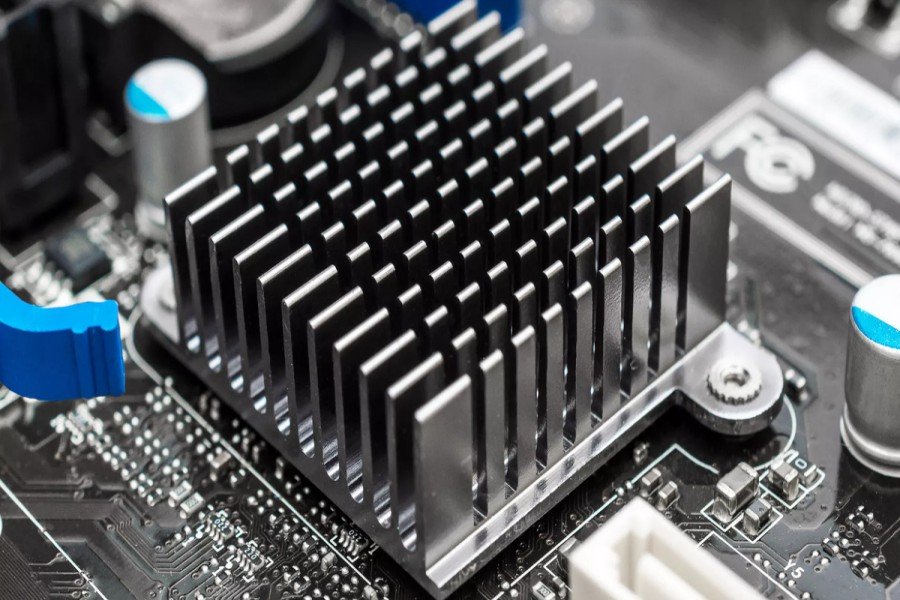

Heat Sink Grinding

Polishing and satin-finishing

Request A Custom Quote

Kingstone’s Robotic Surface Finishing Capabilities

Multi-axis control. Adaptive force sensing. High repeatability.

Feature | Description |

|---|---|

6-7 axis robotic arms | For complex geometry and multi-angle access |

Active force control systems | Real-time adjustment of grinding pressure |

CAD/CAM integration | Enables accurate path planning from 3D models |

Automatic tool changers | Supports multiple abrasive processes in one cycle |

Offline programming | Reduces downtime and accelerates setup |

Dust collection & safety enclosure | Cleanroom-friendly configurations available |

Integrated Automated Solutions

Kingstone Robotics offers automated grinding, polishing, and deburring solutions tailored for the sports equipment industry. From golf clubs to fitness gear, our systems ensure precise finishes, dimensional accuracy, and improved durability. Designed to reduce labor costs, they help manufacturers achieve consistent quality and visual appeal at scale.

Our Integrated Automation Solutions Include:

- Precision Robotic Grinding Cells

- High-Speed Polishing and Buffing Units

- Flexible Deburring Systems for Small Components

- Multi-SKU Robot Complex Units

- Cleanroom-Compatible CNC Polishing Machines

- Vision-Guided Surface Correction Modules

Polishing, Grinding, and Deburring Automation in 3C Electronic Industry Manufacturing

In the world of consumer electronics, finishing quality is both a functional and marketing imperative. Polishing enhances the device’s feel and look, grinding guarantees assembly fit and profile accuracy, and deburring eliminates the safety and structural risks of micro-burrs or casting flash.

Automating these processes brings consistency, scale, and ultra-fine control to an industry defined by slim form factors, premium materials, and high design turnover.

Polishing in 3C electronics is used to remove micro-scratches, oxide layers, and texture inconsistencies on surfaces such as aluminium, stainless steel, or coated plastics. It enhances surface gloss, increases corrosion resistance, and prepares parts for further finishing such as anodising or laser branding.

Common applications include smartphone housings, laptop panels, smartwatches, and camera frames—where a flawless exterior is essential to brand identity and consumer experience.

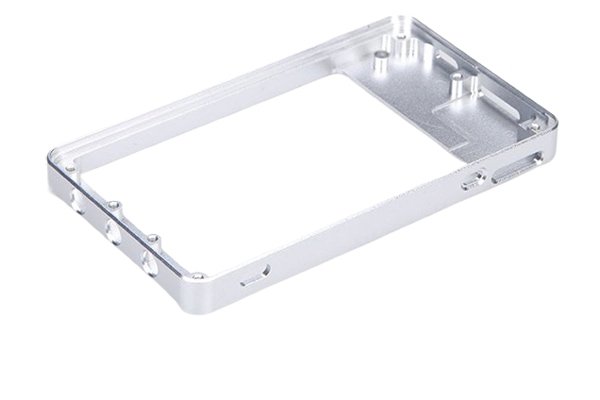

Grinding removes bulk material to shape the final geometry of a part. In 3C applications, this is essential for flatness (e.g., heat sink bases), profile accuracy (e.g., bezels, ports), or aesthetic edge shaping (e.g., unibody casings).

It’s especially critical for parts that must interlock with other components or dissipate heat efficiently, such as processors, battery trays, or contact panels.

Deburring removes sharp metal fragments or extrusion flash left over from machining, die casting, or punching. These burrs may affect assembly tolerances, damage adjacent parts, or interfere with thermal management. Automated deburring ensures these risks are mitigated, consistently and without hand-finishing bottlenecks.

In 3C production, it’s essential for items like internal brackets, port housings, fasteners, and modular chassis parts.

Automated buffing in 3C electronics manufacturing uses soft abrasive wheels or polishing cloths—often with fine polishing compounds—to enhance surface gloss, smoothness, and visual consistency. This process is widely applied to aluminum smartphone frames, stainless steel smartwatch bezels, laptop enclosures, and other visible metal components. It delivers a clean, uniform finish that improves not only aesthetic appeal but also resistance to fingerprints, oxidation, and wear. With precise control and minimal material removal, automated buffing ensures consistent quality across large production volumes, supporting both functional durability and the sleek, premium appearance expected in today’s consumer electronics.

Automate Your Surface Finishing

Tell us about your components—our experts will customise a robotic grinding or polishing solution for your exact needs.

The Role of Automation in Surface Finishing

Polishing Automation

Produces uniform gloss and texture for premium casings and visible components. Minimises human-induced variation, scratches, or inconsistent sheens.

Grinding Automation

Provides fine-tuned edge control and dimensional accuracy for heat-sensitive or shape-critical parts like heat sinks, laptop bases, and camera frames.

Deburring Automation

Removes micro-flash or extrusion burrs in compact electronic frames or slots, supporting clean assembly and long-term mechanical durability.

1. Perfect Aesthetic Consistency at Scale

For 3C products, visual uniformity defines brand quality. Automated polishing ensures the same surface gloss, edge radius, and texture across thousands of parts. Multi-axis robots control motion paths with micrometre precision and can adapt to complex industrial designs.

Used for:

- Mirror-polished smartwatch frames

- Brushed laptop chassis

- Satin-finish smartphone backs

2.Improved Yield and Reduced Rework

Manual grinding or polishing often leads to inconsistent results—especially with complex surfaces or tight radii. Automated systems eliminate human error, tool over-pressure, and edge damage, significantly reducing defect rates and rework costs.

Applicable to:

- High-Mix, Low-Volume (HMLV) production lines

- Premium OEM/ODM supply chains

- Rejected parts due to aesthetic nonconformity

3. Compatibility with Thin and Lightweight Materials

3C components are increasingly thinner, lighter, and more delicate. Our robots use adaptive force control to handle these parts without deformation, while delivering consistent surface conditioning—even on multi-material composites.

Especially important for:

- Magnesium alloy laptop lids

- Thin-wall aluminium bezels

- High-precision camera brackets

4. Higher Throughput, Smaller Footprint

Automated polishing and grinding stations operate continuously, with minimal operator intervention. With multi-fixture design and fast tool switching, one cell can finish hundreds of parts per shift—making automation viable even in compact production lines.

Great for:

- Consumer electronics subcontractors

- OEMs under high seasonal demand

- Multi-line production of colour or finish variants

5. Cleaner and Safer Production Environment

3C manufacturers operate under stringent cleanliness and ESD (electrostatic discharge) standards. Our robotic cells are enclosed, filtered, and ESD-safe—minimising dust, operator exposure, and contamination in high-sensitivity environments.

Valuable for:

- Cleanroom or semi-clean environments

- ISO 14644 or IPC-A-610 class facilities

- Products destined for global compliance (RoHS, REACH, CE)

6. Precision Support for Multi-Finish and Multi-Surface Designs

3C products increasingly feature a combination of textures—such as matte sides, polished frames, and etched logos—within a single part. Robotic systems can be programmed to apply distinct surface treatments in sequence, using position tracking and tool-switch automation to achieve seamless transitions without part repositioning.

Ideal for:

• Smartphones with gradient brushed backs and polished edges

• Wearables with engraved or logo-specific textures

• Multi-finish tablet enclosures with integrated branding zones

Benefits of Automation in Automated Surface Finishing

Why Automate?

Manual surface finishing processes are labor-intensive, time-consuming, and prone to inconsistencies. Automation addresses these challenges by providing:

1. Camera Frame Grinding

Our high-precision 6-axis robotic systems are optimized for finishing delicate enclosures used in DSLR cameras, action cams, and smartphone camera modules. Featuring force-feedback control and vision-guided edge detection, the robots ensure accurate alignment and controlled material removal on micro-scale aluminum, magnesium, and zinc alloy parts.

The process includes automated contour grinding of lens housings, screw hole edges, and frame surfaces, using multi-pass routines to eliminate casting seams, machining marks, and surface oxidation. Real-time monitoring ensures surface roughness below Ra 0.2 μm and verifies dimensional accuracy throughout production.

This solution enhances cosmetic quality and mechanical fit, reduces manual handling risks, and ensures batch-to-batch consistency—ideal for high-volume production of precision optical device enclosures.

2. Phone Case Polishing

Our lightweight, high-speed robotic systems are engineered for polishing a wide range of smartphone cases, tablet back covers, and wearable housings. Equipped with soft polishing heads, compound dispensers, and modular fixtures, the system supports rapid SKU switching and high-mix production. Vision recognition enables accurate model identification and alignment for consistent results across different designs.

The process handles surface polishing of front and rear casings, frame edges, and camera bezels. Optional anti-fingerprint coating and dust removal stages are integrated within the cell. Real-time tracking of polishing parameters—including RPM, pressure, and dwell time—ensures repeatable surface quality.

Ideal for producing premium finishes on plastic, glass, or metal cases, the system enhances product appearance, reduces manual labor, and supports fast-cycle consumer electronics manufacturing.

3. Watch Frame Polishing

Our micro-motion robotic systems are engineered for ultra-precise polishing of miniature watch components, including luxury wristwatch cases, smart watch bezels, and chronograph frames. Equipped with fine force control (±0.1N) and cleanroom-compatible construction, these robots ensure flawless results while protecting delicate geometries and finishes.

The process includes full surface polishing of bezels, lug areas, and crown guards, supporting mirror, brushed, or satin finishes. Optional protective masking preserves engravings and brand elements. An integrated optical inspection system provides real-time visual grading and feedback for consistent aesthetic quality.

This solution delivers showroom-quality results while maintaining edge definition and enhancing both corrosion resistance and durability—ideal for premium watch manufacturing where visual perfection and precision are essential.

4. Heat Sink Grinding

Our high-load robotic systems are designed for precision grinding of aluminum and copper heat sinks used in laptops, desktops, LED units, and power supplies. Equipped with high-torque grinding heads and tool cooling systems, the robots prevent thermal deformation during prolonged cycles. Custom fixtures secure finned or irregular structures to ensure stability and accuracy.

The process includes flat-surface grinding of CPU/GPU contact bases for optimal thermal transfer, as well as deburring of fins, holes, and extrusion marks. Post-grinding stages can integrate thermal paste or coating applications.

This automated solution improves surface flatness, enhances cooling efficiency, and ensures tight mechanical fit. Scalable and configurable, it supports a wide range of OEM sink geometries and high-volume production needs.

Trusted in Automation Since 1993

Backed by decades of experience and partnerships with leading global brands.