Aerospace Industry

Advanced Grinding Solutions for Aerospace and Power Applications

At Kingstone Robotics, our robotic grinding and polishing systems are designed to meet the extreme demands of the aerospace and power generation industries. We specialize in precision surface finishing for high-performance components—whether you’re dealing with large aerospace casings or small, intricate parts like turbine blades. Our systems are capable of processing advanced materials such as Inconel, titanium alloys, stainless steel, and ceramic-coated parts, ensuring dimensional accuracy, surface integrity, and repeatable results. Automation not only increases throughput but also eliminates operator variability, making it a key enabler for next-generation aerospace manufacturing.

Why Surface Finishing Matters in Aerospace

Surface finishing directly affects mechanical performance, such as fatigue life, corrosion resistance, and aerodynamic flow.

Aerospace components often operate under extreme stress and temperature—meaning even microscopic surface defects can lead to failure.

High-value parts such as fan blades, stator vanes, nozzles, and bearing housings require controlled, repeatable finishes for quality assurance and certification compliance (AS9100, NADCAP, etc.).

Challenges of Manual Finishing in Aerospace

Labour-intensive. Inconsistent. Expensive.

- Manual grinding and polishing of aerospace parts is slow, inconsistent, and difficult to scale.

- Skilled operators are required to meet tight dimensional tolerances and RA (roughness average) specs—yet human fatigue and variation often compromise quality.

- Many aerospace alloys are hard-to-machine or heat-sensitive, requiring precise pressure and path control, which robotic automation excels at.

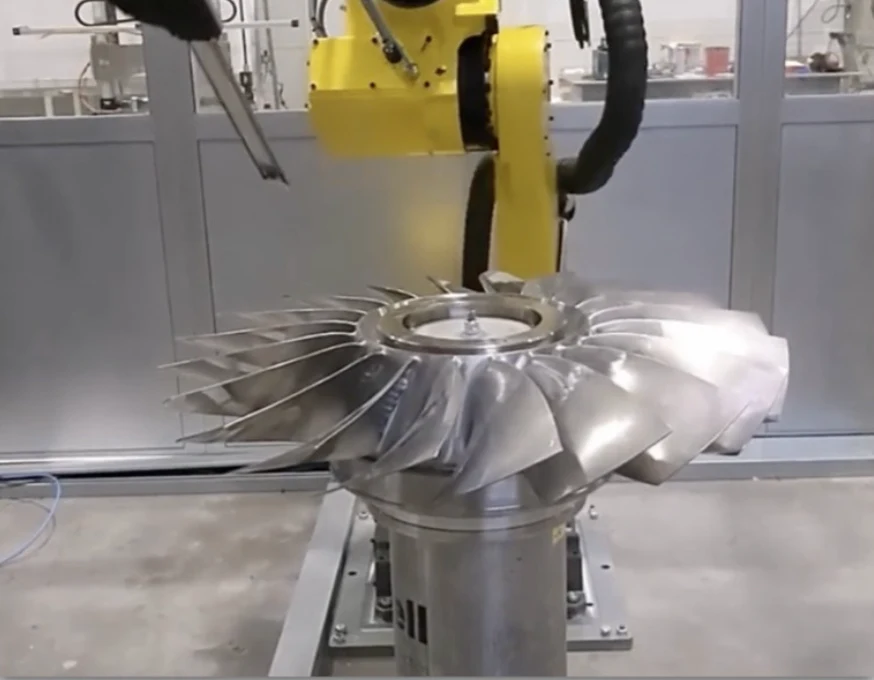

Turbine blade polishing

Aerospace pin grinding

Turbine blade polishing

Diamond wheels grinding

Polishing and satin-finishing

Polishing and satin-finishing

Request A Custom Quote

Kingstone’s Robotic Surface Finishing Capabilities

Multi-axis control. Adaptive force sensing. High repeatability.

Feature | Description |

|---|---|

6-7 axis robotic arms | For complex geometry and multi-angle access |

Active force control systems | Real-time adjustment of grinding pressure |

CAD/CAM integration | Enables accurate path planning from 3D models |

Automatic tool changers | Supports multiple abrasive processes in one cycle |

Offline programming | Reduces downtime and accelerates setup |

Dust collection & safety enclosure | Cleanroom-friendly configurations available |

Integrated Automated Solutions

Kingstone Robotics is a specialized provider of automated grinding, polishing, and deburring systems tailored explicitly for aerospace manufacturing. Leveraging state-of-the-art automated technology and in-house engineered robotic systems, we deliver customized, precise, and consistent surface finishing solutions that meet stringent aerospace quality standards.

Our Integrated Automation Solutions Include:

- Automatic Grinding Station

- Automatic Grinding and Polishing Machine

- Automatic Buffing Unit

- Robotic Deburring Station

- Robot Complex Unit

- CNC Polishing Machine

Polishing, Grinding, and Deburring Automation in Aerospace Industry Manufacturing

In the aerospace industry, the need for high-precision, safety-critical, and performance-optimized components is paramount. To meet these rigorous requirements, aerospace manufacturers are adopting automated solutions for surface finishing processes such as polishing, grinding, and deburring. These automated techniques play a vital role in enhancing the structural integrity, aerodynamic efficiency, and longevity of aerospace parts.

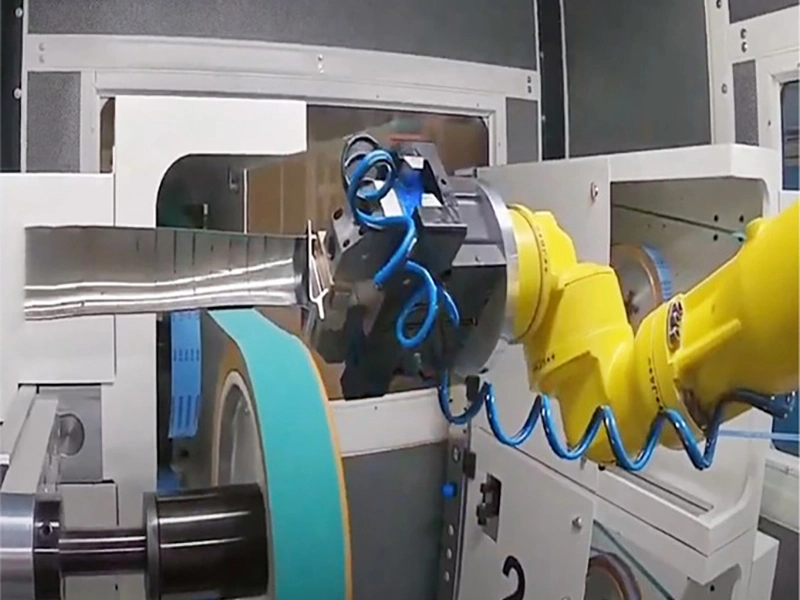

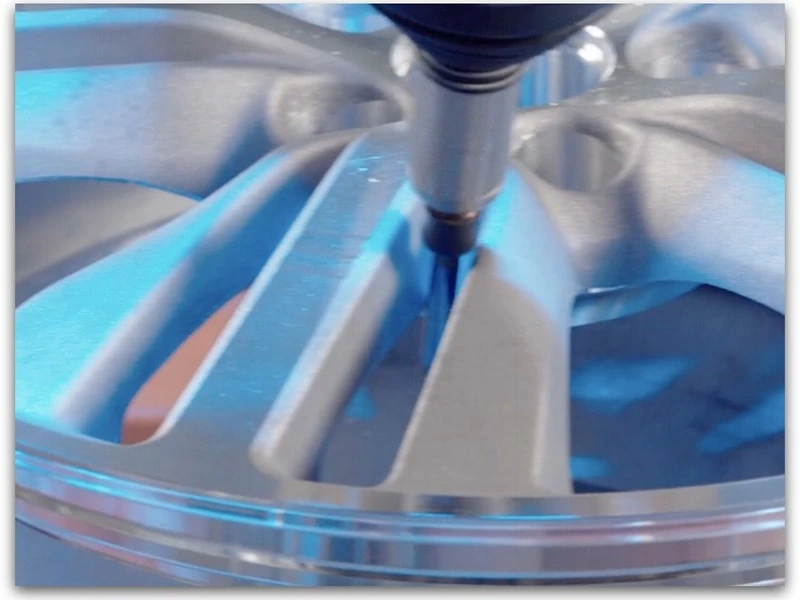

Automated polishing uses robotic arms or CNC machines to apply abrasives in a controlled manner, creating smooth and reflective surfaces on aerospace components. It ensures uniform finish quality, eliminates human inconsistency, and is ideal for parts requiring low surface roughness, such as turbine blades or precision housings.

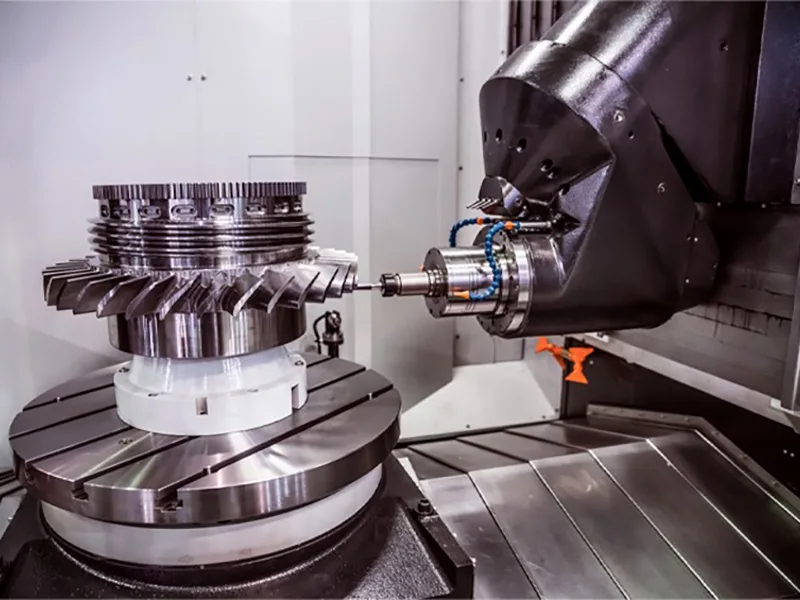

Automated grinding involves robotic or mechanized systems removing excess material or shaping aerospace parts with abrasive tools. This process achieves tight dimensional tolerances and consistent geometry, making it essential for hard-to-machine alloys like Inconel and titanium used in jet engines and structural parts.

Automated deburring removes sharp edges, burrs, and residual material left from machining or casting. Robotic systems detect and remove these imperfections precisely, improving part safety, fit, and readiness for coating or assembly—especially critical in aerospace parts like gear components or brackets.

Automated buffing uses soft abrasive wheels or cloths, often with polishing compounds, to enhance surface gloss and uniformity. In aerospace manufacturing, it is commonly applied to aluminum panels, interior cabin parts, or decorative components, achieving an aesthetically clean finish with minimal surface abrasion.

Automate Your Surface Finishing

Tell us about your components—our experts will customise a robotic grinding or polishing solution for your exact needs.

The Role of Automation in Surface Finishing

Polishing Automation

Used for fan blades, turbine vanes, and housing surfaces. Robotic polishing ensures low surface roughness (Ra<0.2μm) and uniform aerodynamic contours.

Grinding Automation

Automated CNC and robotic grinding for aerospace pins, shafts, and rotor disks enhances geometric accuracy and part interchangeability.

Deburring Automation

Removes critical-edge burrs in structural frames, fasteners, and casing components. Essential for reducing fatigue failure risk in flight-critical parts.

1. Consistent Quality and Precision

Automated systems deliver uniform finishes across every part, eliminating variation caused by manual labor and ensuring repeatable results that meet OEM standards.

2. Increased Throughput

Robots can operate continuously with minimal downtime, significantly increasing production speed and output—ideal for high-volume automotive manufacturing.

3. Improved Worker Safety

Automation reduces human exposure to dust, noise, and vibration from grinding and polishing, creating a safer work environment.

4. Tight Tolerance Control

Robotic grinding and polishing can achieve precise dimensional tolerances and surface roughness values, critical for fit and performance.

5. Lower Operational Costs

While initial investment is higher, automated systems reduce long-term costs by lowering labor expenses, minimizing rework, and extending tool life.

6. Flexible Integration

Modern robotic workstations can be reprogrammed for different parts or surface treatments, making them adaptable for model changes and varied automotive components.

Benefits of Automation in Automated Surface Finishing

Why Automate?

Manual surface finishing processes are labor-intensive, time-consuming, and prone to inconsistencies. Automation addresses these challenges by providing:

1. Turbine Blade Grinding And Deburring Automation

Our robotic grinding system is built around 6-axis units with a wide payload range (60–2300 kg) and adaptive force control, ensuring precise, consistent pressure across complex blade surfaces. It supports grinding of nickel and titanium alloys using custom-designed heads, all within an enclosed cell featuring dust extraction and thermal compensation. The system handles both grinding and edge deburring in a fully automated cycle, with real-time path correction to adapt to blade curvature and wear. It can be quickly configured for different blade sizes and geometries.

This solution achieves surface roughness as low as Ra 0.1–0.3 μm while minimizing thermal deformation, ensuring smooth finishes and enhanced aerodynamic performance. It provides consistent edge blending and supports AS9100 compliance, making it ideal for processing turbine blades, engine fan blades, stator vanes, and integrated airfoil components in aerospace manufacturing.

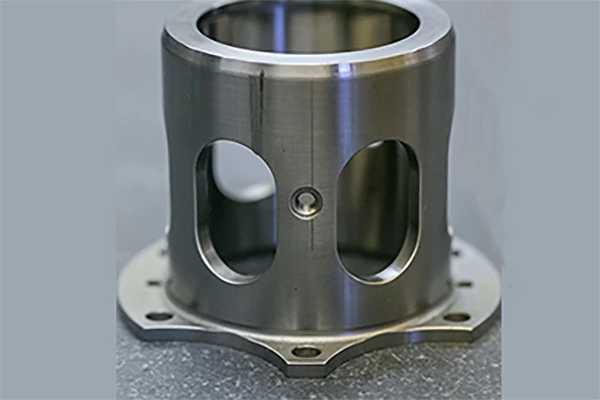

2. Aerospace Wheel Hub Grinding and Deburring

Our robotic solution for aerospace wheel hub grinding and deburring combines integrated robots for precision finishing of rotating parts such as brake hubs and landing gear components. It features high-precision fixtures that ensure accurate clamping of round and concentric surfaces, with built-in sensors for part detection and position feedback. The system includes an enclosed housing option for dust control and operator safety, along with an automated tool change mechanism for seamless switching between grinding and deburring tasks.

This fully automated station enables efficient material handling, real-time part alignment, and onboard quality verification using machine vision. It ensures accurate finishing of aluminum and carbon composite brake hubs, improving roundness and hub-to-bearing alignment. The reduction in manual handling lowers the need for secondary inspection, delivering repeatable, high-quality results for both civil and military aircraft applications, including wheel hubs, brake drums, axle interfaces, and landing gear assemblies.

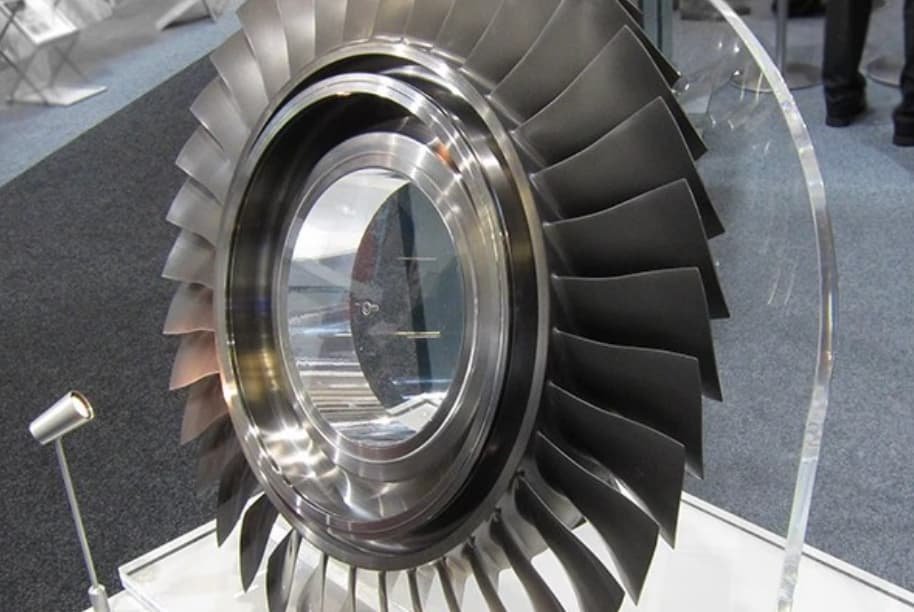

3. Fan Case & Blisk Buffing Automation

Our robotic buffing system is designed for large, curved aerospace components like fan cases and blisks. Multi-axis robotic arms, flexible buffing pads, and intelligent path programming ensure precise control on complex geometries. Optional media monitoring and automatic reloading enhance process stability. Satin and mirror finishes can be completed in one cycle, with quick tool changes to support varied surface requirements.

This solution handles both inner and outer surfaces of hollow parts, delivering uniform finishes that reduce drag and improve airflow. It lowers surface stress without affecting thickness and maintains high repeatability for large production runs. Ideal for fan cases, diffuser housings, nacelle components, ring structures, and integrally bladed rotors.

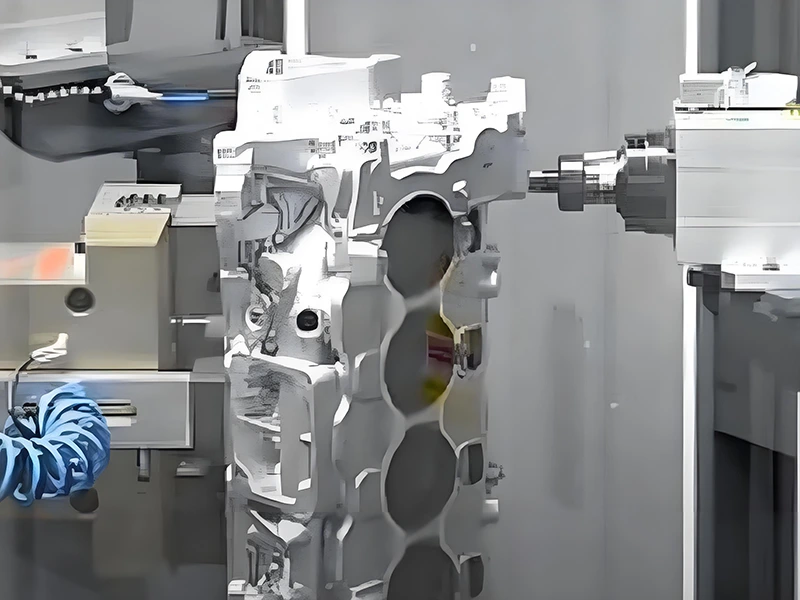

4. Engine Case Deburring Automation

Our compact robotic deburring units are engineered for internal engine case structures, offering flexible arm reach and multi-tool spindle systems capable of processing bores, ribs, and edges. The fully enclosed design supports inline deployment with a small footprint. Abrasive tools are compatible with both titanium and stainless steel, ensuring effective removal in demanding aerospace environments.

This single-station solution is configurable for various case diameters, bore depths, and cavity angles. Integrated PLC and vision systems adjust tool paths in real time to suit part variability. It reliably removes burrs from hard-to-reach internal features, minimizes cycle interruptions, preserves structural integrity, and improves sealing surface accuracy for better assembly fit.

Trusted in Automation Since 1993

Backed by decades of experience and partnerships with leading global brands.