Newsletter

Request Our Latest Product Catalog

Get detailed specs, applications, and custom options for our robotic polishing, grinding, and deburring systems.

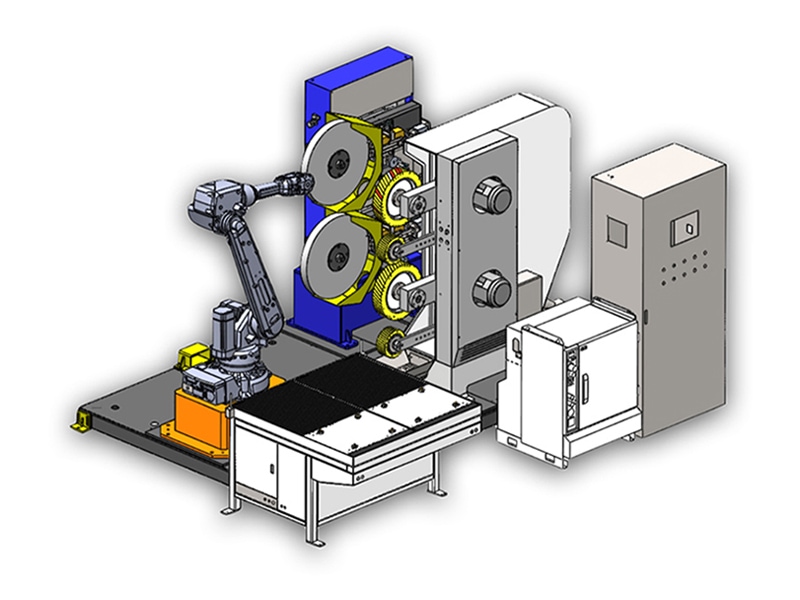

| Parameter | Specification |

|---|---|

| Unit Type | Robotic Grinding & Polishing Unit |

| Robot Brand | ABB, KUKA, FANUC, or specify the brand |

| Robot Weight | 20kg–100kg |

| Sander Machine | 2–6 set |

| Buffer Machine | 1–2 set |

| PLC Brand | Siemens, Schneider, or specify the brand |

| Polishing Consumables | Cloth wheel, sisal wheel, sand flap wheel |

| Grinding Consumables | Sand belt, foam wheel, sanding wheel, rubber wheel |

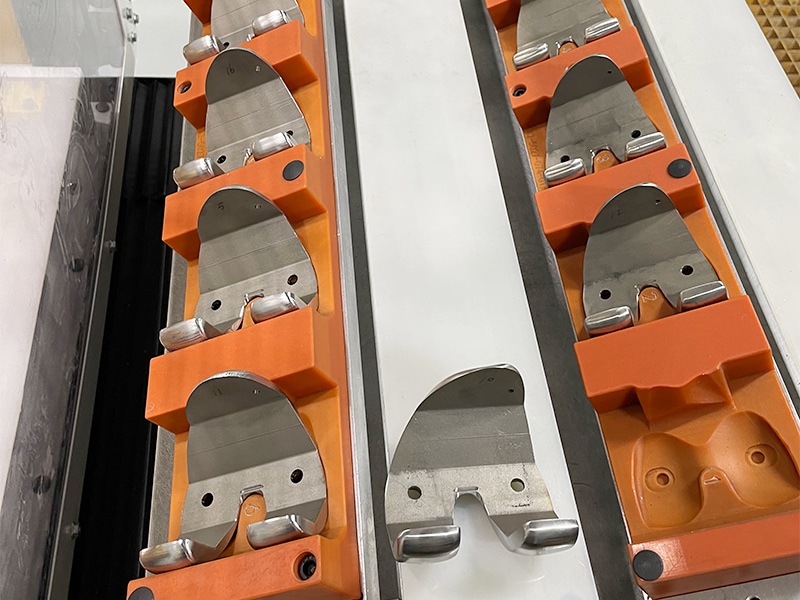

KS will design detailed grinding & polishing unit parameters based on the product and the desired grinding and polishing effect. The process of each product is not fixed, we are providing tailor-made automation solutions.We provide turnkey projects, including fixture design, workpiece 3D drawing generation, equipment layout drawing, floor space 3D drawing and process schematic diagram.

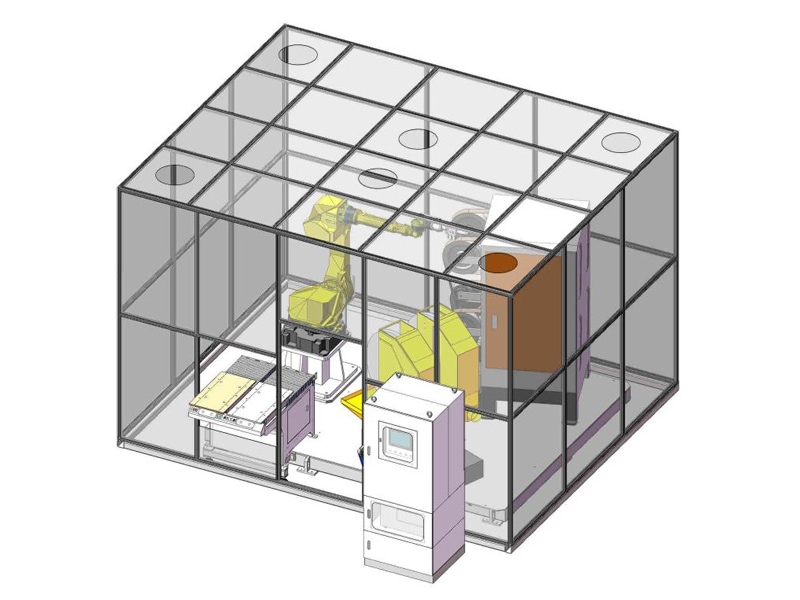

KS will design detailed grinding & polishing unit parameters based on the product and the desired grinding and polishing effect. The process of each product is not fixed, we are providing tailor-made automation solutions.We provide turnkey projects, including fixture design, workpiece 3D drawing generation, equipment layout drawing, floor space 3D drawing and process schematic diagram.  Effect drawing of grinding & polishing unit system with aluminum alloy dustproof polishing room (note: aluminum alloy dustproof polishing room is optional)

Effect drawing of grinding & polishing unit system with aluminum alloy dustproof polishing room (note: aluminum alloy dustproof polishing room is optional)

Our core technologies—automatic constant-pressure control, multifunctional fixtures, composite polishing wheels, and a proprietary software system—enable precise, consistent finishing on complex surfaces. Our solution fills a critical gap in the surface treatment industry.

From castings to bathroom hardware, we design robotic grinding and polishing systems tailored to your production needs.

Product

Copyright © 2025 Kingstone Robotics. All rights reserved.

Get detailed specs, applications, and custom options for our robotic polishing, grinding, and deburring systems.