New Energy Industry

Advanced Grinding Solutions for New Energy Industry Applications

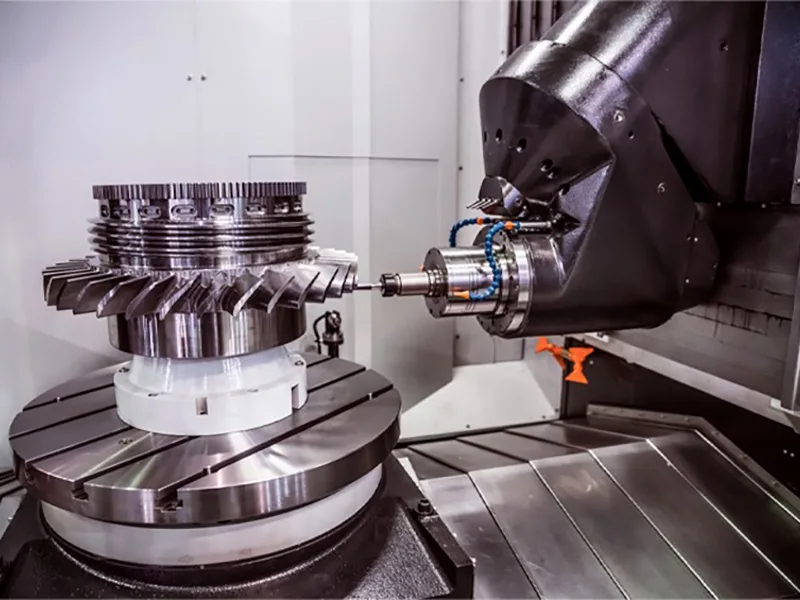

At Kingstone Robotics, our robotic grinding and polishing systems are engineered to meet the rigorous demands of the new energy sector—including wind, hydrogen, and advanced battery technologies. We specialize in precision surface finishing for high-performance components, from large cast housings in wind turbine gearboxes to fine-detailed parts like fuel cell plates and battery casings. Our systems are capable of processing advanced materials such as stainless steel, aluminum alloys, titanium, and coated composites, ensuring dimensional accuracy, surface integrity, and consistent finish quality.

Automation significantly improves production throughput while eliminating manual variability—critical for maintaining efficiency, repeatability, and traceability in clean energy manufacturing. Whether you’re producing structural components for offshore wind or precision plates for electrolyzers, our robotic finishing solutions help meet industry standards for safety, performance, and reliability in next-generation energy systems.

Why Surface Finishing Matters in New Energy

- Surface finishing plays a critical role in the mechanical performance of new energy components, directly impacting fatigue life, corrosion resistance, thermal efficiency, and sealing integrity.

- In sectors like wind, hydrogen, and battery energy storage, components often operate under continuous load, variable temperatures, and harsh environmental conditions. Even microscopic surface imperfections can accelerate wear, reduce electrical insulation, or compromise sealing—leading to reduced efficiency or premature failure.

- High-value parts such as wind turbine shafts, hydrogen electrolyzer plates, inverter cooling plates, and battery enclosures require highly consistent, repeatable surface finishes to meet performance benchmarks and certification standards (e.g., ISO 1940, IEC 61400, UL 2580). Precise finishing not only ensures reliability and safety but also enables downstream processes like coating, welding, and assembly in clean energy system manufacturing.

Challenges of Manual Finishing in New Energy

- Manual grinding and polishing of new energy components—like battery enclosures, turbine shafts, or fuel cell plates—is slow, variable, and hard to scale. Skilled labor is needed to meet strict Ra surface finish and dimensional specs, but human fatigue often leads to inconsistent results.

- Materials common in clean energy—such as stainless steel, coated aluminum, and heat-treated alloys—are difficult to process by hand. They demand precise, repeatable pressure and motion control—areas where robotic automation delivers faster, safer, and more consistent outcomes.

Base Castings Grinding

batteryTray Grinding

Charging Pile Polishing

Connector Grinding

Solar Bracket Grinding

Polishing and satin-finishing

Request A Custom Quote

Kingstone’s Robotic Surface Finishing Capabilities

Multi-axis control. Adaptive force sensing. High repeatability.

Feature | Description |

|---|---|

6-7 axis robotic arms | For complex geometry and multi-angle access |

Active force control systems | Real-time adjustment of grinding pressure |

CAD/CAM integration | Enables accurate path planning from 3D models |

Automatic tool changers | Supports multiple abrasive processes in one cycle |

Offline programming | Reduces downtime and accelerates setup |

Dust collection & safety enclosure | Cleanroom-friendly configurations available |

Integrated Automated Solutions

Kingstone Robotics delivers specialized robotic grinding, polishing, and deburring systems tailored for the new energy sector. Our advanced automation solutions enhance the manufacturing of components critical to electric vehicles, renewable energy systems, and energy storage technologies. By integrating precision robotics with intelligent control systems, we provide consistent, high-quality surface finishing that meets the stringent standards of the new energy industry.

Our Integrated Automation Solutions Include:

- Automatic Grinding Station

- Automatic Grinding and Polishing Machine

- Automatic Buffing Unit

- Robotic Deburring Station

- Robot Complex Unit

- CNC Polishing Machine

Polishing, Grinding, and Deburring Automation in New Energy Industry Manufacturing

The new energy industry demands components with high precision, durability, and aesthetic appeal. Automated surface finishing processes such as grinding, polishing, and deburring are essential in achieving these requirements. Kingstone Robotics’ solutions are designed to handle complex geometries and diverse materials, ensuring optimal performance and longevity of new energy products.

Enhances the appearance and corrosion resistance of charging piles and battery enclosures, ensuring consumer appeal and longevity.

Achieves precise dimensions in battery trays and base castings, critical for structural integrity and assembly compatibility.

Removes imperfections from connectors and solar brackets, improving safety and ensuring reliable electrical connections..

Automated buffing uses soft abrasive wheels or polishing cloths, often with fine compounds, to improve surface gloss, cleanliness, and uniformity. In the new energy sector, it is commonly applied to components such as battery enclosures, inverter housings, hydrogen fuel cell plates, and wind turbine covers. The process delivers a visually clean, uniform finish with minimal material removal—ideal for improving corrosion resistance, coating adhesion, or electrical contact surfaces in high-performance clean energy systems.

Automate Your Surface Finishing

Tell us about your components—our experts will customise a robotic grinding or polishing solution for your exact needs.

The Role of Automation in Surface Finishing

Polishing Automation

Enhances the appearance and corrosion resistance of charging piles and battery enclosures, ensuring consumer appeal and longevity.

Grinding Automation

Achieves precise dimensions in battery trays and base castings, critical for structural integrity and assembly compatibility.

Deburring Automation

Removes imperfections from connectors and solar brackets, improving safety and ensuring reliable electrical connections.

1. Consistent Quality and Precision

Automated finishing guarantees surface quality and dimensional accuracy across every part. With adaptive force control and real-time feedback, grinding and polishing remain stable on variable geometries and material hardness.

Whether for:

- A CNC-machined axle end

- A large-scale gearbox cover

- Or a multi-surface traction component

Our robotic cells maintain precision, even in demanding production environments.

2. Increased Productivity and Throughput

Combining robotic arms, automatic tool changers, and coordinated motion control, our systems reduce cycle times and increase part throughput. Automation is especially beneficial in processing high-volume, heavy components where manual labor is inefficient.

Whether for:

- Batch production of coupler housings

- High-speed connector grinding

- Or polishing large traction rods

Automation allows your line to operate at peak efficiency.

3. Improved Worker Safety

Manual surface finishing in the rail sector often involves heavy tools, hot workpieces, and hazardous dust. Our robotic systems eliminate direct operator contact, reducing risk of injury and improving air quality on the shop floor.

Whether for:

- Grinding sharp edges off cast iron parts

- Deburring welded assemblies

- Or polishing stainless structural elements

Robotic automation shields workers from high-risk processes.

4. Lower Operating Costs

Automation reduces labor dependency, scrap rates, and inspection failures. With predictive maintenance and tool life monitoring, total cost of ownership is optimized for long-term operations.

Whether for:

- Repair workshops needing repeatable results

- OEMs standardizing multi-part production

- Or tier-one rail suppliers scaling for volume

Automation delivers cost savings and measurable ROI.

5. Better Integration with Smart Manufacturing

Kingstone’s systems are designed for integration into digital production environments. Robots can interface with MES/ERP systems, provide finishing data (roughness, pass/fail rates), and adapt toolpaths via real-time sensors or vision systems.

Whether for:

- Industry 4.0 compliance

- Data-driven quality assurance

- Or flexible production lines with frequent product changeovers

Our automation solutions prepare your factory for the evolving demands of energy system manufacturing.

6. Precision Finishing for Lightweight and Mixed-Material Assemblies

New energy systems often involve lightweight alloys, composite housings, and multi-material assemblies that require distinct surface treatments. Robotic finishing systems adapt force, speed, and tool type in real time—preventing delamination, overheating, or over-polishing, while ensuring consistent finishes across diverse material zones.

Ideal for:

• EV battery enclosures combining aluminum and polymer inserts

• Inverter casings with coated heat-dissipation surfaces

• Solar panel brackets requiring both weld cleanup and anodizing prep

Benefits of Automation in Automated Surface Finishing

Why Automate?

Manual surface finishing processes are labor-intensive, time-consuming, and prone to inconsistencies. Automation addresses these challenges by providing:

1. Base Castings Grinding

Our heavy-duty 6-axis robotic grinding systems are engineered to process large aluminum castings used in EV platforms and energy storage systems. With payloads up to 300 kg, these robots handle die-cast or sand-cast motor bases, inverter housings, and subframe components. Equipped with custom abrasive heads, rotary positioners, and vision-guided alignment, the system ensures full-area access and precision across flat, ribbed, and contoured surfaces.

A multi-pass grinding program removes flashing, parting lines, and surface irregularities. Closed-loop monitoring adjusts for thickness and flatness deviations in real time, while automated tool wear management ensures consistent finish quality. Fully enclosed cells support dust control and mist suppression, making this ideal for inline deployment in EV chassis or battery box production, with minimal human supervision and maximum consistency.

2. Battery Tray Grinding

Our robotic solution for aerospace wheel hub grinding and deburring combines integrated robots for precision finishing of rotating parts such as brake hubs and landing gear components. It features high-precision fixtures that ensure accurate clamping of round and concentric surfaces, with built-in sensors for part detection and position feedback. The system includes an enclosed housing option for dust control and operator safety, along with an automated tool change mechanism for seamless switching between grinding and deburring tasks.

This fully automated station enables efficient material handling, real-time part alignment, and onboard quality verification using machine vision. It ensures accurate finishing of aluminum and carbon composite brake hubs, improving roundness and hub-to-bearing alignment. The reduction in manual handling lowers the need for secondary inspection, delivering repeatable, high-quality results for both civil and military aircraft applications, including wheel hubs, brake drums, axle interfaces, and landing gear assemblies.

3. Charging Pile Polishing

Our robotic polishing systems—featuring collaborative or industrial 6-axis arms—are built for aluminum and stainless steel casings used in EV charging piles, fast-charging units, and energy kiosks. Equipped with tool changers for flap wheels, buffing cloths, and polishing pastes, the system delivers flexible, multi-surface treatment. Anti-scratch detection protects pre-coated or painted surfaces.

Each cell handles weld mark removal, pre-polishing, and final finish—whether high-gloss or matte—based on design specs. Automated orientation enables full 360° multi-sided polishing, and optional modules apply anti-fingerprint or weather-resistant coatings.

This solution ensures showroom-quality finishes, enhances UV and corrosion resistance, and supports high visual consistency for public-facing infrastructure. It reduces manual labor while improving both production efficiency and brand image across energy hardware installations.

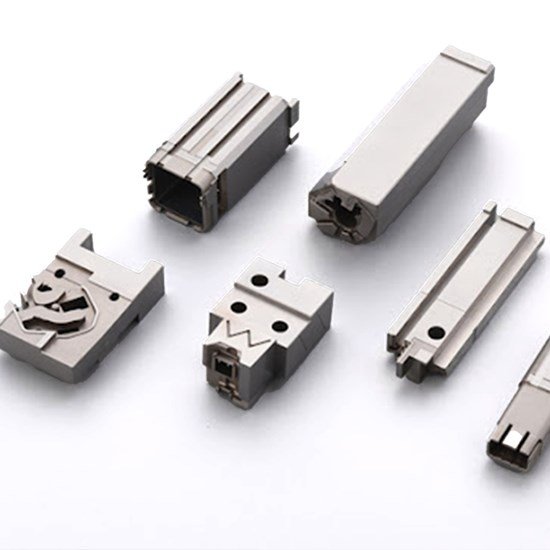

4. Connector Grinding

Our compact, high-speed robotic systems are designed for precision finishing of battery connectors, high-voltage plug terminals, and energy module interconnects. Equipped with micro-grinding spindles operating at over 20,000 rpm, the system delivers fine edge control for aluminum, zinc, or magnesium die-cast parts. Custom jigs secure small or delicate profiles, with optional dual-robot setups for complex handling.

Integrated processes include terminal chamfering, flange grinding, burr removal, and flash cleanup. ESD-safe tooling and anti-vibration platforms protect part integrity. Camera-assisted burr detection ensures positional accuracy, while inline cleaning and ejection streamline quality control.

Ideal for high-mix, small-batch production, this setup ensures safe, interference-free connections, minimizes thermal distortion, and improves dimensional precision—supporting scalable, high-quality manufacturing of energy electronics components.

Trusted in Automation Since 1993

Backed by decades of experience and partnerships with leading global brands.