Automated Surface Finishing In Rail Transiit Industry

Advanced Grinding Solutions for Rail Transit Industry Applications

At Kingstone Robotics, our robotic grinding and polishing systems are built to handle the rigorous demands of the rail transit industry. We specialize in precision surface finishing for high-performance rail components—whether it’s large welded steel frames, bogie assemblies, or detailed parts like brake discs and axle housings. Our systems can process a range of heavy-duty materials including high-strength steel, stainless alloys, and cast components, delivering consistent dimensional accuracy and surface quality. By automating these finishing tasks, we help rail manufacturers improve throughput, reduce manual labor, and ensure reliable, repeatable results that meet industry safety and performance standards—essential for modern rail vehicle production and maintenance.

Why Surface Finishing Matters in Rail Transit

- Surface finishing directly influences mechanical performance in rail applications, impacting fatigue life, corrosion resistance, and long-term structural integrity.

- Rail components are often exposed to heavy mechanical loads, vibration, and harsh environmental conditions—meaning even minor surface defects can lead to crack initiation, premature wear, or component failure over time.

- Critical parts such as wheelsets, brake rotors, axle housings, and coupling systems require consistent, repeatable surface finishes to meet performance standards and safety certifications (e.g., ISO 9001, EN 15085, IRIS). Achieving proper surface condition is essential not only for operational reliability but also for compliance with rigorous inspection protocols throughout a rail vehicle’s service life.

Challenges of Manual Finishing in Rail Transit

Labour-Intensive. Inconsistent. Costly.

Manual grinding and polishing of rail components is time-consuming, inconsistent, and hard to scale for high-volume production or refurbishment programs. Achieving the required dimensional tolerances and surface roughness (Ra) often depends heavily on skilled labor—but even experienced operators are prone to variation and fatigue, leading to quality inconsistencies.

Many rail-critical materials—such as high-strength steels and corrosion-resistant alloys—are challenging to process manually due to their hardness or thermal sensitivity. These conditions demand precise control of contact pressure, speed, and path—factors that robotic systems manage with far greater accuracy and repeatability.

Railway Bearing Grinding

Transmission Box Grinding

Connectror Bracket Grinding

Seat Frame Grinding

Traction Bar Grinding

Polishing and satin-finishing

Request A Custom Quote

Kingstone’s Robotic Surface Finishing Capabilities

Multi-axis control. Adaptive force sensing. High repeatability.

Feature | Description |

|---|---|

6-7 axis robotic arms | For complex geometry and multi-angle access |

Active force control systems | Real-time adjustment of grinding pressure |

CAD/CAM integration | Enables accurate path planning from 3D models |

Automatic tool changers | Supports multiple abrasive processes in one cycle |

Offline programming | Reduces downtime and accelerates setup |

Dust collection & safety enclosure | Cleanroom-friendly configurations available |

Integrated Automated Solutions

Kingstone Robotics is a trusted provider of robotic grinding, polishing, and deburring systems engineered for the rail transit industry. Leveraging proprietary automation technology and precision robotic integration, we help manufacturers improve part consistency, reduce manual labor, and enhance the durability and safety of railway components. Our systems are purpose-built to meet the high standards of railway equipment manufacturing and maintenance.

Our Integrated Automation Solutions Include:

- Automatic Grinding Station

- Automatic Grinding and Polishing Machine

- Automatic Buffing Unit

- Robotic Deburring Station

- Robot Complex Unit

- CNC Polishing Machine

Polishing, Grinding, and Deburring Automation in Rail Transit Industry Manufacturing

The rail transit industry demands large, rugged components with tight tolerances and long service lives. Automated polishing, grinding, and deburring play a critical role in achieving these goals by ensuring high-quality surface finishing across structural, drivetrain, and mechanical subsystems. Kingstone’s robotic systems are optimized for components like bogies, connectors, bearings, and housings—delivering consistent results even on complex surfaces.

Polishing is a mechanical finishing process that reduces surface roughness, enhances aesthetics, and improves corrosion resistance. In the rail industry, polishing is especially important for stainless-steel covers, brackets, and external-facing structures to ensure smooth visual lines and environmental durability.

Automated grinding involves robotic or mechanized systems removing excess material or shaping aerospace parts with abrasive tools. This process achieves tight dimensional tolerances and consistent geometry, making it essential for hard-to-machine alloys like Inconel and titanium used in jet engines and structural parts.

Deburring removes sharp edges and residual burrs left after casting, machining, or welding. In railway component assembly, burrs can impair fitment, create safety hazards, or reduce fatigue life. Automated deburring ensures clean edges, smooth mating surfaces, and long-term structural integrity.

Automated buffing in rail transit manufacturing uses soft abrasive wheels or polishing cloths—often combined with buffing compounds—to enhance surface gloss, smoothness, and visual consistency. This process is widely used on stainless steel or aluminum exterior panels, interior trims, handrails, and other visible components in passenger trains and metro cars. It delivers a clean, uniform finish that improves both aesthetics and corrosion resistance, while minimizing material removal and ensuring consistent quality across large production volumes.

Automate Your Surface Finishing

Tell us about your components—our experts will customise a robotic grinding or polishing solution for your exact needs.

The Role of Automation in Surface Finishing

Polishing Automation

Applied to outer covers, housings, and welded joints to improve appearance and environmental resistance. Robotic polishing achieves consistent surface textures and eliminates manual variability.

Grinding Automation

Used for precision finishing of structural parts like shafts, bars, and brackets. Ensures geometry, balance, and surface quality for high-load rail systems.

Deburring Automation

Removes weld spatter, casting flash, and machining burrs from safety-critical components. Supports clean assembly and extends fatigue life under dynamic loads.

1. Consistent Quality and Precision

Automated finishing guarantees surface quality and dimensional accuracy across every part. With adaptive force control and real-time feedback, grinding and polishing remain stable on variable geometries and material hardness.

Whether for:

- A CNC-machined axle end

- A large-scale gearbox cover

- Or a multi-surface traction component

Our robotic cells maintain precision, even in demanding production environments.

2. Increased Productivity and Throughput

Combining robotic arms, automatic tool changers, and coordinated motion control, our systems reduce cycle times and increase part throughput. Automation is especially beneficial in processing high-volume, heavy components where manual labor is inefficient.

Whether for:

- Batch production of coupler housings

- High-speed connector grinding

- Or polishing large traction rods

Automation allows your line to operate at peak efficiency.

3. Improved Worker Safety

Manual surface finishing in the rail sector often involves heavy tools, hot workpieces, and hazardous dust. Our robotic systems eliminate direct operator contact, reducing risk of injury and improving air quality on the shop floor.

Whether for:

- Grinding sharp edges off cast iron parts

- Deburring welded assemblies

- Or polishing stainless structural elements

Robotic automation shields workers from high-risk processes.

4. Tight Tolerance Control

Automation reduces labor dependency, scrap rates, and inspection failures. With predictive maintenance and tool life monitoring, total cost of ownership is optimized for long-term operations.

Whether for:

- Repair workshops needing repeatable results

- OEMs standardizing multi-part production

- Or tier-one rail suppliers scaling for volume

Automation delivers cost savings and measurable ROI.

5. High-Quality Finishing for Large and Complex Geometries

Rail components—such as bogies, couplers, and drive housings—often feature large dimensions, multi-surface transitions, and hard-to-reach contours. Robotic systems equipped with extended-reach arms and multi-axis flexibility ensure uniform surface quality across every face, angle, and recess—something manual processes struggle to achieve at scale.

Applicable to:

• Oversized gearbox casings with internal cavities

• Welded bogie frames requiring uniform deburring

• Multi-axis surface prep before painting or coating

6. Seamless Integration into Heavy Industry Workflows

Kingstone’s robotic surface finishing systems are built to integrate with upstream and downstream operations, including robotic welding, CNC machining, NDT, and coating. With programmable logic, digital traceability, and MES/ERP compatibility, they support rail OEMs and MRO facilities in building fully automated and auditable production lines.

Ideal for:

• Tier-1 rail suppliers embracing Industry 4.0 principles

• Smart factories needing cross-process visibility

• MRO operations standardizing surface repair and refinishing routines

Benefits of Automation in Automated Surface Finishing

Why Automate?

Manual surface finishing processes are labor-intensive, time-consuming, and prone to inconsistencies. Automation addresses these challenges by providing:

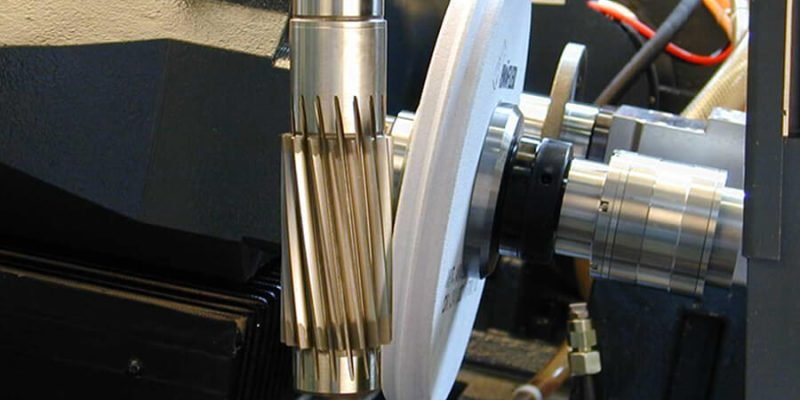

1. Railway Bearing Grinding

Our robotic grinding systems are tailored for rail components like axle journals, wheel hub seats, and bogie shafts. Using 6-axis robotic arms with up to 230 kg payloads and precision rotary indexers, the system delivers multi-angle access and accurate surface control. Real-time force sensing and custom end-of-arm tooling ensure uniform pressure and finish on cylindrical and conical geometries.

The process includes roughing, semi-finishing, and final polishing, with automated loading via conveyors or gantry systems. Integrated in-line gauging and closed-loop feedback allow real-time adjustments for part deviation or thermal effects.

Benefits include consistent Ra < 0.4 μm, reduced rework, and elimination of manual fatigue—ideal for high-volume, safety-critical rail component production.

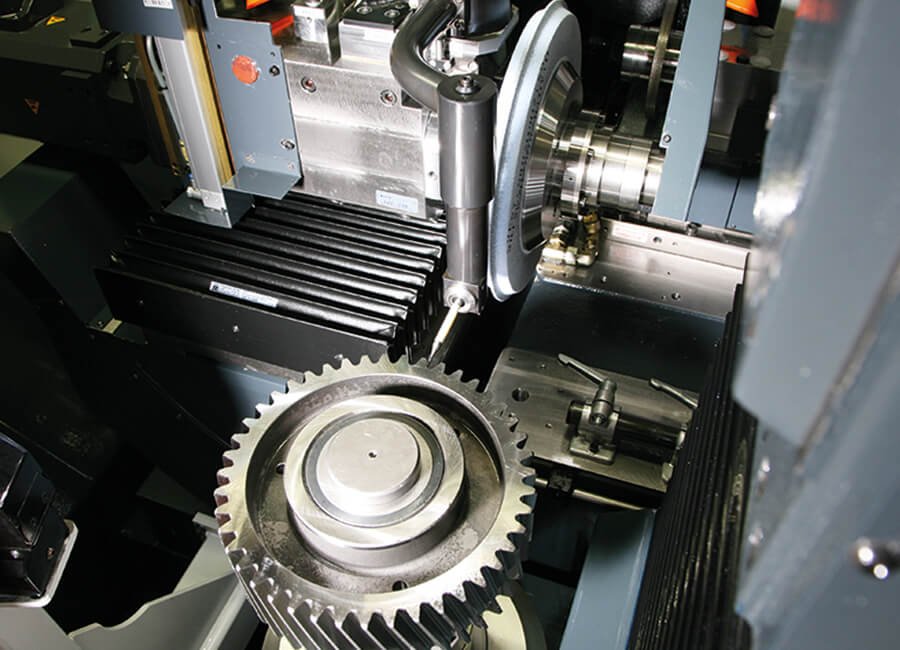

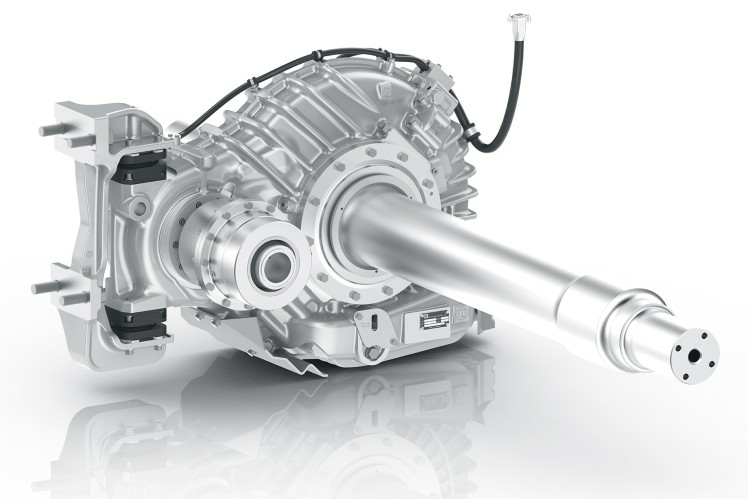

2. Transmission Box Grinding

Our compact robotic systems are engineered for internal and external finishing of rail drivetrain components such as transmission covers, differential housings, and reducer enclosures. Featuring flexible-arm robots and multi-tool spindles, they handle bores, ribs, and edges with precision. The enclosed design supports inline deployment and is compatible with titanium and stainless-steel abrasives.

Single-station robotic cells perform grinding on mating planes and casting surfaces with configurable paths tailored to varying wall thicknesses. Integrated PLC control, dust extraction, coolant delivery, and optical scanning ensure flatness within 0.05 mm and real-time path correction.

This solution eliminates flash, seams, and oxidation, reducing downstream defects while delivering consistent quality across gearbox SKUs. It significantly shortens processing time compared to manual or multi-station setups.

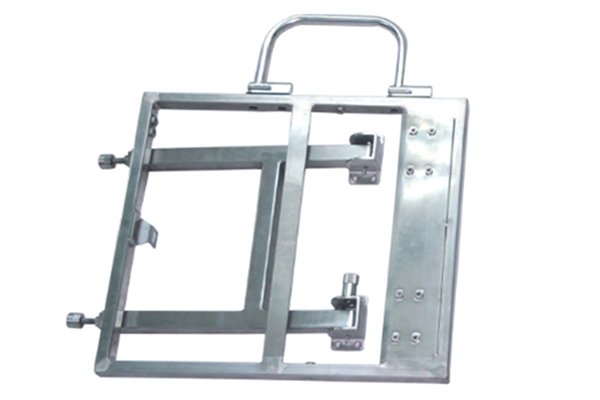

3. Connector Bracket Grinding

Our high-speed robotic cells are designed for precision finishing of rail transit brackets, link plates, and connectors. Featuring dual-position rotary tables, these cells allow simultaneous loading and processing, maximizing throughput. Adaptive spindle torque control handles both thin-walled and heat-treated steel alloys, while vision alignment ensures precise edge and hole targeting.

Automated processes include grinding of bolt holes, flanges, and contours, followed by fine abrasive polishing to prep surfaces for welding, coating, or assembly. Robot-integrated cameras validate edge quality in real time, while modular fixtures allow fast switching between part types.

The system removes burrs without distorting the material, improving fatigue life and structural reliability—ideal for finishing mounting brackets, sensor housings, and electrical interface parts in rail vehicle production.

4. Traction Bar Grinding

Our robotic finishing systems are optimized for rail traction link rods, stabilizer bars, and suspension arms. Medium-payload robotic arms equipped with high-power belt grinders ensure uniform material removal along curved and linear surfaces. Adaptive contact wheels and custom fixtures handle irregular profiles and asymmetrical geometries with precision.

The system removes weld seams and blends profiles in a single pass, maintaining consistent grinding force along the entire component. Edge radiusing enhances fatigue resistance, while integrated sensors validate surface roughness between Ra 0.6–0.8 μm—ideal for paint prep and visual consistency.

Enclosed cells with spark and dust control ensure safety and cleanliness. Minimal fixture changeover enables fast adaptation for part variants within the same product family, reducing downtime and supporting high-throughput rail manufacturing lines.

Trusted in Automation Since 1993

Backed by decades of experience and partnerships with leading global brands.