Furniture Hardware

Furniture Hardware

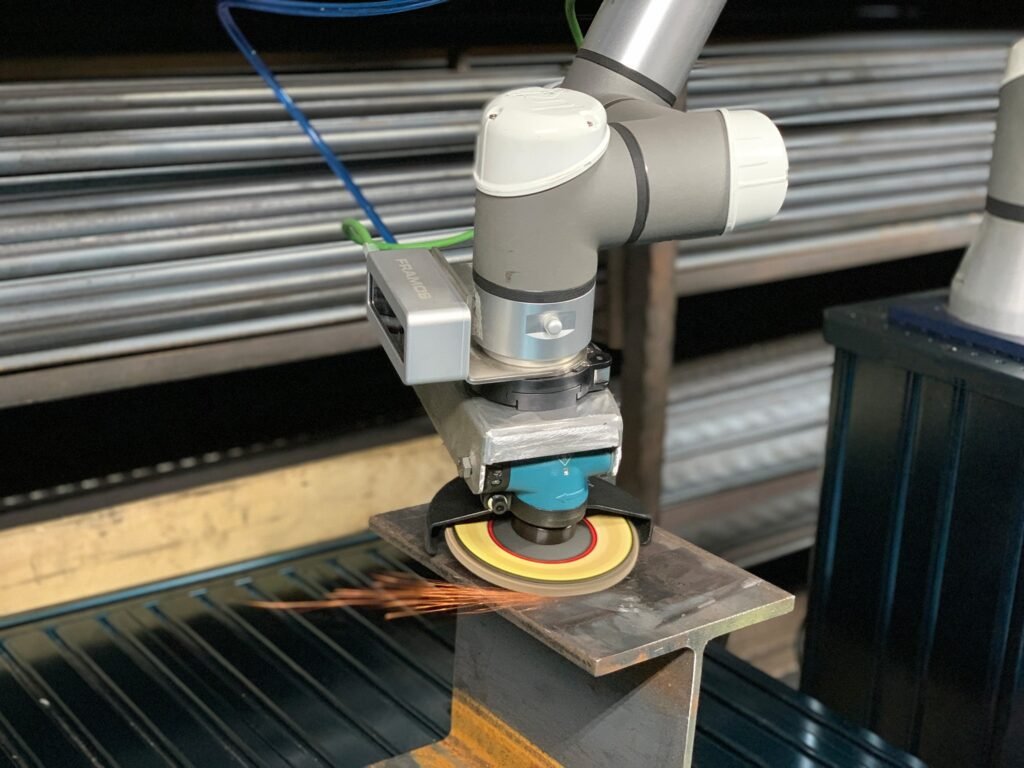

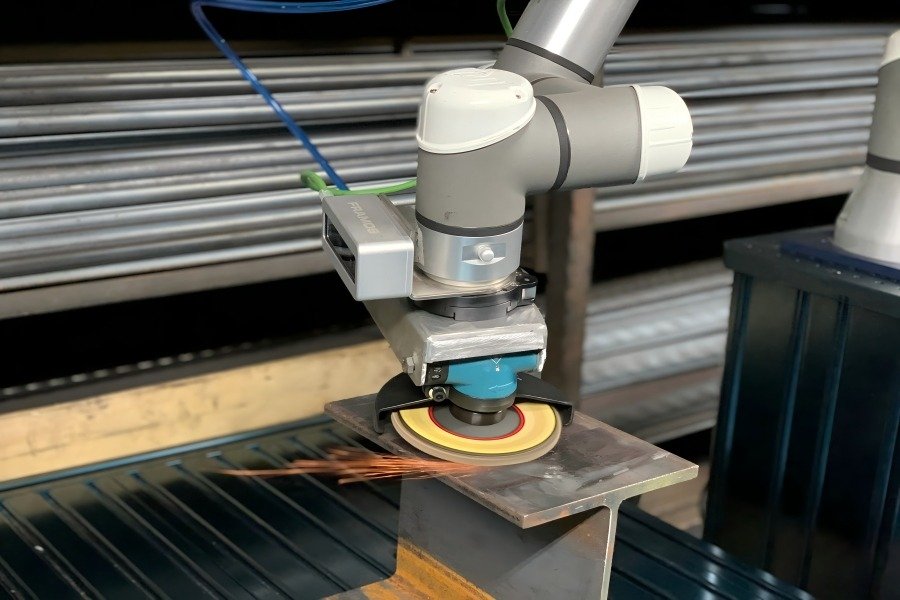

Polishing and grinding robot system, after comparison, the robot equipment has higher grinding accuracy than manual grinding of furniture connectors, such as aluminum chair legs, effectively improving the product qualification rate and service life, thus greatly improving the use effect of the furniture.

Chair leg grinding

Furniture legs polishing

Dining table legs grinding

Gas burners deburring

Coffee tamper polishing

Automation solutions

Request A Custom Quote

Furniture Hardware

Furniture hardware must meet high standards in finish, uniformity, and repeatability—whether for dining table legs, gas burner frames, or coffee tampers. Precision matters in both mass production and custom design.

Kingstone Robotics provides automated grinding, polishing, and deburring solutions for varied materials and shapes, boosting quality and reducing manual labor.

Our Integrated Automation Solutions Include:

- Robotic Grinding Stations for Welded and Cast Components

- Multi-Axis Polishing Units for Contoured or Ornamental Shapes

- Flexible Deburring Cells for Precision-Edge Refinement

- High-Throughput Buffing Machines for Decorative Surfaces

- Vision-Driven Finishing Systems for Multi-Profile Part Detection

- Toolpath Programming Compatible with Design-CAD Integration

Polishing, Grinding, and Deburring in Furniture Hardware Manufacturing

In furniture hardware, surface finishing is more than cosmetic—it affects functionality, touch feel, assembly alignment, and corrosion resistance. Consumers expect flawless, smooth hardware on chairs, tables, cabinets, or stoves. Automation ensures that expectation is consistently met, regardless of production volume or component complexity.

what is Polishing?

Polishing enhances the visual and tactile quality of hardware by refining its surface to a smooth or mirror-like finish. In furniture, this applies to stainless steel legs, brass knobs, and aluminium tampers where appearance, fingerprint resistance, and smoothness are crucial for the user experience.

What is Grinding?

Grinding removes welds, casting seams, or shape deviations from structural parts such as chair legs, table feet, or large metal frames. It is critical to ensure flatness, alignment, and mechanical compatibility prior to coating, painting, or assembly.

What is Deburring?

Deburring eliminates sharp edges, casting flash, or machining remnants that can affect both safety and aesthetic uniformity. Robotic deburring is particularly important for parts that users frequently touch—door handles, taps, gas burner rings, and fittings—where imperfections are immediately noticeable.

Automation in Surface Finishing Is Applied to Furniture Hardware Components Including:

- Dining table and chair legs (stainless steel, wood, aluminium)

- Sofa feet and cabinet stands

- Kitchen appliance burner frames and grates

- Towel bars, robe hooks, and furniture-mounted accessories

- Coffee tamper handles and espresso machine accessories

- Furniture hardware for hospitality, residential, and luxury segments

Kingstone Robotics Project Cases

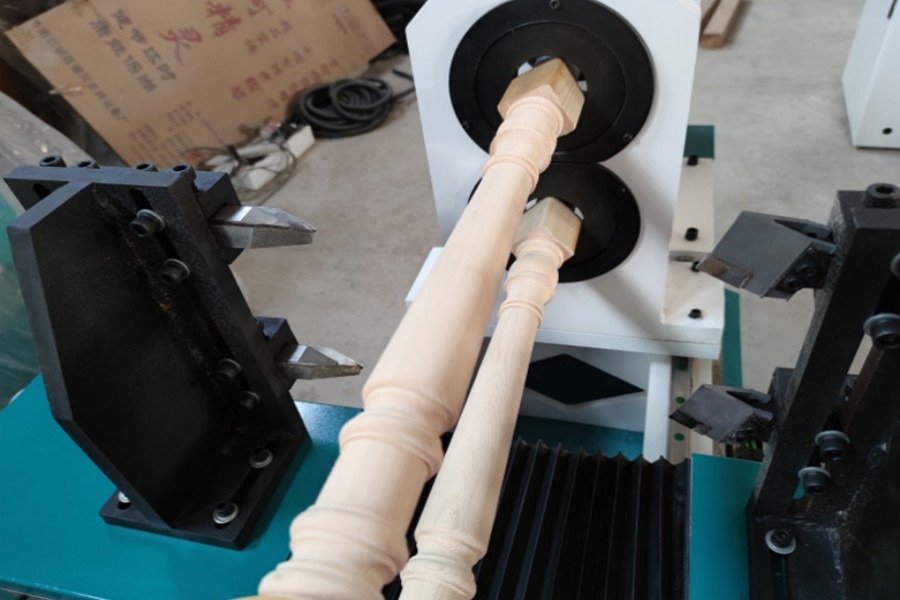

1. Chair Leg Grinding

2. Furniture Legs Polishing

Polishing Automation

The Role of Automation in Surface Finishing

Polishing Automation

Delivers consistent sheen, finish, and texture across a range of shapes and materials. Ideal for decorative hardware with curved or multi-surface geometries.

Grinding Automation

Ensures flat contact surfaces and consistent contouring across welded or cast furniture supports. Also improves powder coating or plating adhesion.

Deburring Automation

Eliminates rough edges or safety risks from small fittings, knobs, or appliance accessories, ensuring ready-to-use components with minimal post-processing.

Benefits of Automation in Automated Surface Finishing

Why Automate?

Manual surface finishing processes are labor-intensive, time-consuming, and prone to inconsistencies. Automation addresses these challenges by providing:

1. Consistent Quality and Aesthetic Uniformity

From a brushed table leg to a polished espresso tamper, visual consistency is essential for market acceptance. Robotic systems offer repeatable motion control and stable tool pressure, producing flawless finishes batch after batch.

Applies to:

- Brushed stainless or chrome hardware

- Coated or powder-finished knobs and legs

- Multi-finish collections with consistent style

2. Support for High-Mix, Low-Volume Manufacturing

The furniture industry is driven by variety and seasonal design changes. Our robotic solutions offer fast setup and adaptive path control, enabling efficient production even for small series or custom orders.

Ideal for:

- Premium hospitality or contract furniture

- Boutique design studios or B2B OEMs

- Bespoke finishes for luxury product lines

4. Enhanced Safety and Worker Ergonomics

Manual polishing and grinding in furniture production involve vibration, airborne particles, heat, and repetitive strain. Automating these tasks not only reduces workplace risk but improves operator well-being and retention.

Supports:

- Safer, dust-controlled working environments

- Ergonomic shift management

- Modern compliance with workplace health regulations

3. Increased Throughput Without Compromising Detail

One robotic cell can replace multiple manual workers, delivering round-the-clock polishing and grinding. With tool-change automation and multi-fixture designs, cycle times are reduced while maintaining artisanal-grade detail.

Enables:

- High-speed processing of symmetrical parts

- Multi-surface finishing within a single robotic cycle

- Lean manufacturing strategies

6. Adaptability to Complex Shapes and Mixed Materials

Furniture hardware frequently incorporates blended contours, recessed surfaces, and material combinations like metal-plastic or coated alloys. Robotic systems equipped with multi-axis articulation and adaptive force control can finish complex geometries with high precision—achieving uniform results without damaging adjacent surfaces.

Suitable for:

• Decorative knobs with inlaid materials or layered construction

• Curved chair legs or contoured table brackets

• Multi-finish assemblies combining matte and gloss zones

5. Lower Operational Costs and Scrap Rates

With precision tool pressure, wear detection, and in-process monitoring, robotic systems reduce over-polishing, tool misuse, or accidental part damage. This leads to higher first-pass yield and optimised consumable usage.

Useful for:

- High-polish components like coffee tampers and decorative handles

- Finishing parts with tight dimensional tolerances

- Reducing manual rework in quality control

1. Chair Leg Grinding

Robotic Configuration:

- Six-axis robotic arms equipped with force-controlled grinding tools, ensuring consistent material removal on curved and angled surfaces.

- Integration with vision systems for precise alignment and adaptation to various chair leg designs.

- Customizable end-effectors to accommodate different materials, such as wood, metal, or plastic.

Process Integration:

- Automated grinding of chair legs to remove surface imperfections, weld seams, or casting marks.

- Preparation of surfaces for subsequent polishing, painting, or coating processes.

- Real-time monitoring of grinding parameters to ensure quality and consistency.

Key Benefits:

- Enhanced surface finish and uniformity across all chair legs.

- Increased production efficiency and reduced manual labor.

- Improved worker safety by minimizing exposure to dust and repetitive tasks.

Applications:

- Wooden, metal, or plastic chair legs in residential, commercial, or institutional furniture.

2. Furniture Legs Polishing

Robotic Configuration:

- Robotic polishing systems with adaptive force control to handle various leg shapes and materials.

- Equipped with interchangeable polishing heads for different finishes, such as matte, satin, or mirror.

- Integration with dust extraction systems to maintain a clean working environment.

Process Integration:

- Automated polishing of furniture legs to achieve desired surface finishes.

- Removal of minor surface defects and preparation for final assembly or packaging.

- Inline inspection systems to ensure consistent quality across all units.

Key Benefits:

- Consistent and high-quality surface finishes on furniture legs.

- Reduced production time and labor costs.

- Enhanced product appeal and customer satisfaction.

Applications:

- Legs of sofas, tables, chairs, and other furniture items made from various materials.

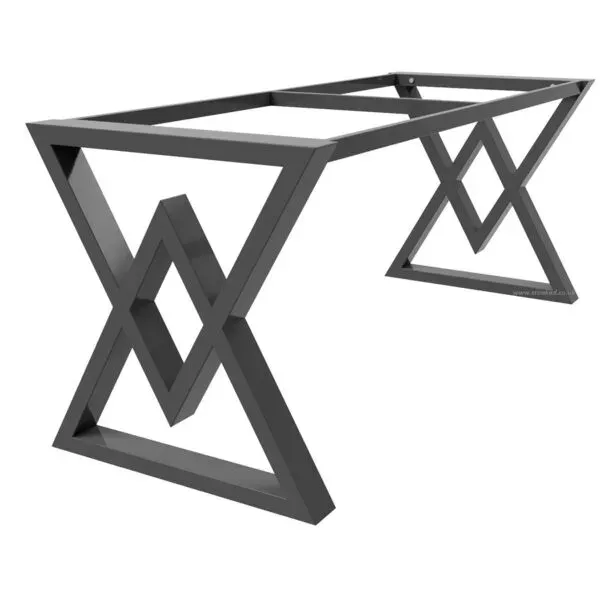

3. Dining Table Legs Grinding

Robotic Configuration:

- High-precision robotic arms with programmable grinding paths to accommodate complex leg designs.

- Integration with CNC systems for seamless operation and control.

- Safety enclosures with dust and noise reduction features.

Process Integration:

- Automated grinding of dining table legs to remove weld seams, casting marks, or surface irregularities.

- Preparation of surfaces for polishing, painting, or coating processes.

- Real-time monitoring and adjustment of grinding parameters for optimal results.

Key Benefits:

- Improved surface quality and uniformity of dining table legs.

- Increased production throughput and consistency.

- Reduced manual labor and associated costs.

Applications:

- Dining table legs made from wood, metal, or composite materials in various styles and designs.

4. Gas Burners Deburring

Robotic Configuration:

- Robotic deburring systems equipped with compliant tools to handle intricate burner geometries.

- Integration with vision systems for precise detection and removal of burrs.

- Programmable paths to adapt to different burner designs and sizes.

Process Integration:

- Automated deburring of gas burner components to remove sharp edges and burrs resulting from casting or machining.

- Preparation of components for assembly, coating, or further processing.

- Inline inspection to ensure all burrs are effectively removed.

Key Benefits:

- Enhanced safety and functionality of gas burners.

- Improved fit and finish of assembled components.

- Reduced risk of defects and rework.

Applications:

- Gas burners used in kitchen appliances, heating systems, or industrial equipment.

5. Coffee Tamper Polishing

Robotic Configuration:

- Precision robotic polishing systems with fine abrasive tools suitable for small, intricate components.

- Adaptive force control to prevent over-polishing or damage to delicate surfaces.

- Integration with handling systems for efficient loading and unloading.

Process Integration:

Automated polishing of coffee tampers to achieve a smooth, high-gloss finish.

- Removal of surface imperfections and preparation for branding or packaging.

- Quality control checks to ensure consistent finish across all units.

Key Benefits:

- Enhanced aesthetic appeal and tactile feel of coffee tampers.

- Increased production efficiency and consistency.

- Reduced manual labor and potential for human error.

Applications:

- Coffee tampers used in professional and home espresso machines, made from materials like stainless steel, aluminum, or wood.

Trusted in Automation Since 1993

Backed by decades of experience and partnerships with leading global brands.

Request A Custom Quote

Automate Your Surface Finishing

Tell us about your components—our experts will customise a robotic grinding or polishing solution for your exact needs.