Introduction

In manufacturing, polishing spans a diverse set of tasks—from refining delicate medical implants to finishing large metal panels in automotive and aerospace production. Each application presents unique challenges in terms of part geometry, surface contact, and motion control. That’s why selecting the right robotic arm is not just a technical decision, but a strategic one.

This article outlines the key types of robotic arms commonly used for polishing operations:

- SCARA robots – ideal for high-speed, planar operations

- Six-axis articulated robots – offering full-range motion and versatility

- Cartesian (gantry) systems – optimized for large, flat work areas

- Collaborative robots (cobots) – designed for safe human-machine interaction

Each of these robotic arm types brings specific mechanical structures and motion characteristics that affect polishing performance, system complexity, and integration cost. Choosing the right solution requires a clear understanding of your production requirements, including:

- Surface finish specifications

- Part size and shape

- Workspace constraints

- Force and path control needs

While robot arm pricing can range from $15,000 to over $100,000 depending on type and configuration, it’s important to recognize that hardware costs are only part of the equation. Integration, end-of-arm tooling, safety systems, and software add significant value—and expense—to a robotic polishing system. Those aspects will be explored in detail in a follow-up article.

For now, this guide focuses on the core features and approximate base pricing of each robot type in the U.S. market, providing a practical foundation for decision-makers seeking to automate polishing operations.

SCARA Robots for Polishing – Features and Cost Range

SCARA robots feature a rigid but lightweight structure with two parallel rotary joints for X-Y plane movement, plus vertical Z-axis motion and limited wrist rotation. This configuration is ideal for flat or slightly contoured surfaces where the orientation of the polishing tool doesn’t need to change dynamically.

In polishing applications, SCARAs excel at speed and repeatability, especially for planar operations such as polishing flat surfaces, rotating discs, or the top of a fixed part. These robots are often mounted overhead or within tight enclosures, taking advantage of their small footprint. However, due to their four-axis constraint, SCARAs cannot effectively handle complex angles or contours. Their motion is inherently limited to predefined planes unless enhanced by an external tilting mechanism.

Payload capacity is generally modest—ranging from about 5 to 20 kilograms—and reach is typically under one meter. While these limits make SCARAs unsuitable for large or heavy components, they are well-suited to compact setups or dedicated cells for repetitive tasks.

From a cost perspective, SCARAs are among the most affordable robot types. Entry-level models start around $8,000, with mid-range systems priced around $25,000 to $40,000 depending on specifications. High-performance SCARAs with longer reach or specialized features can exceed $50,000. ABB, for example, offers SCARA systems for about $8,000 at the low end. Standard Bots estimates typical prices from $25,000 to over $100,000 depending on payload, speed, and integration options. For polishing applications, a SCARA unit capable of handling 10 kg payloads and 1-meter reach might cost approximately $50,000.

Despite the variance, SCARAs offer a cost-effective entry point into robotic polishing, especially when the application demands planar movement and moderate force. They combine compactness with efficiency, provided the job’s geometry doesn’t require frequent tool reorientation.

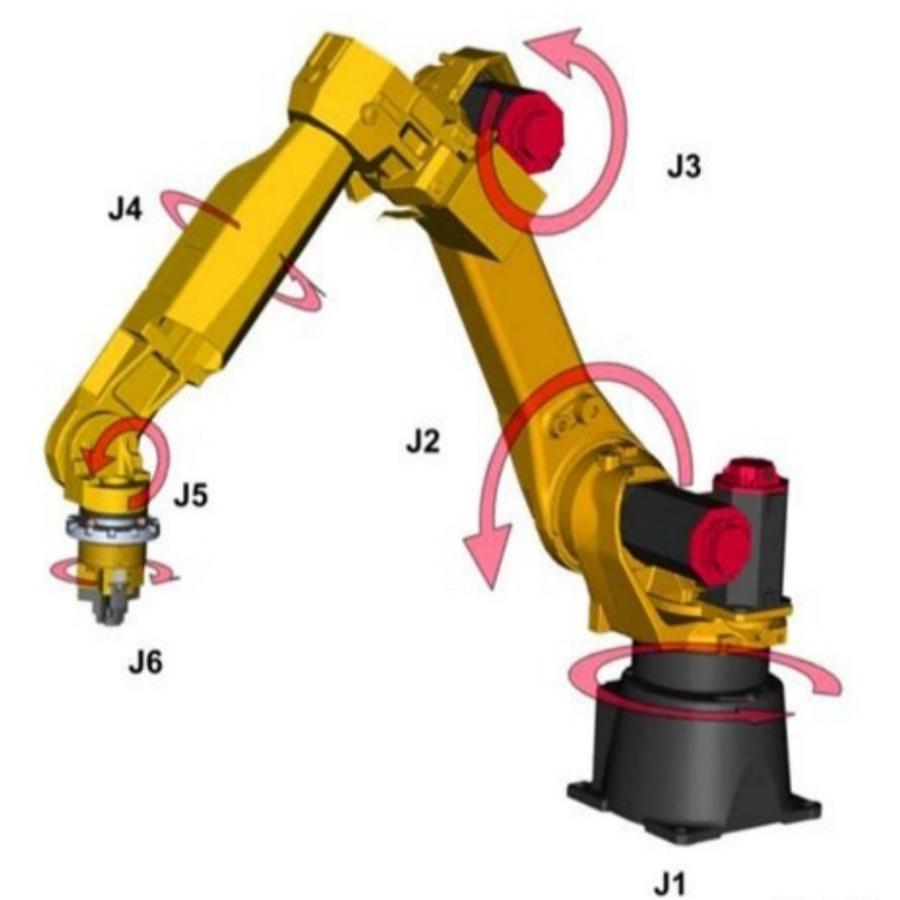

Six-Axis Articulated Robots – Features and Cost Range

The six-axis articulated arm is the workhorse of industrial robotics. Its design mimics the range of motion of a human arm, with six rotational joints that enable motion in any direction and full control over orientation. This flexibility is essential in polishing tasks involving curved, angled, or irregular surfaces. A six-axis arm can approach a surface from various angles, adjust tool contact continuously, and maintain polishing force even on complex contours.

Applications in automotive, aerospace, and heavy equipment manufacturing rely heavily on these robots for tasks like polishing curved metal panels, buffing headlight covers, or finishing weld seams. Thanks to their reach—often between one and 2.5 meters—and payload capacities ranging from 6 kg to over 300 kg, six-axis robots are versatile enough to serve both small parts and large assemblies.

However, this flexibility comes at a price. Articulated robots are more expensive than SCARAs due to their complexity. Entry-level six-axis units with light payload capacity start around $30,000. Mid-sized industrial models, like the FANUC M-20iA or ABB’s IRB 2600, typically fall between $50,000 and $100,000. Higher-payload units from KUKA or ABB, capable of handling 120 to 150 kg, may cost upwards of $120,000. The largest robots—such as FANUC’s 1200-kg payload series—can exceed $400,000, though these are rarely needed in polishing applications.

Precision also varies across the range. While six-axis robots generally provide ±0.05 mm repeatability, high-end models offer better accuracy and durability under load. The ability to mount on the floor, wall, or ceiling adds deployment flexibility, which is especially useful in multi-axis polishing scenarios.

In summary, a mid-sized six-axis robot for polishing can be expected to cost $50,000 to $80,000. When versatility and multi-angle motion are essential, these robots deliver the necessary capability at a justifiable price.

Cartesian (Gantry) Robots – Features and Cost Range

Cartesian robots, also known as gantry robots, are built with linear actuators that move along X, Y, and Z axes. They offer a straightforward design and excel in precision tasks over flat or planar workspaces. For polishing large metal sheets, glass panels, or mold surfaces, a Cartesian robot provides reliable straight-line motion and can be scaled to cover large areas economically.

These systems are inherently rigid, making them ideal for applications requiring consistent downward or lateral pressure. They can carry significant payloads, although the absence of rotation in the standard three-axis setup limits their usefulness for contoured surfaces unless additional axes or wrist actuators are included.

Cost-wise, Cartesian systems are among the most economical choices for basic tasks. Entry-level systems for small areas may start at $5,000, with mid-range configurations priced between $10,000 and $20,000. For example, igus offers the drylin® E series starting around $5,000. Larger gantries with longer travel or heavier-duty components might reach $50,000 or more. However, for most polishing applications involving flat or lightly contoured parts, a well-built Cartesian robot priced around $20,000–$30,000 is sufficient.

Their modular design makes Cartesians ideal for custom polishing stations. Provided the job doesn’t demand frequent orientation changes, Cartesian robots offer excellent performance-to-cost ratio.

Collaborative Robots (Cobots) – A Special Mention

Collaborative robots, or cobots, are designed for safe interaction with humans and are increasingly popular in polishing due to their ease of use and built-in safety features. While technically similar to six-axis articulated arms, cobots are equipped with torque sensors, speed limiters, and emergency stop capabilities that allow them to operate without protective cages.

Cobots excel in applications that involve delicate surface finishing or close human supervision. Their programming interfaces are often intuitive, requiring minimal training or coding. Force control features make them particularly suitable for light polishing tasks where maintaining consistent pressure is key.

Cobots generally support payloads below 20 kg and operate at slower speeds than traditional industrial robots. This trade-off ensures safety but limits throughput. However, in small-batch or high-mix production settings, their flexibility and ease of deployment often outweigh the speed limitations.

Prices for cobots vary slightly above or in line with traditional six-axis robots. Universal Robots’ lineup includes the UR5e($45,000), and UR20 (~$60,000). FANUC’s CRX series starts around $40,000 and can exceed $80,000 for high-capacity models. ABB’s GoFa and KUKA’s LBR series offer similar pricing and feature sets. Standard Bots’ RO1, a cost-effective cobot option, starts at under $30,000 and includes modern AI tools for rapid deployment.

For light-duty polishing in environments where flexibility and safety are paramount, cobots represent a viable solution. They may cost more upfront in some cases, but the savings on integration and safety hardware often balance the budget.

Matching the Robot Type to Your Polishing Needs

Selecting the right robot begins with defining your application. For simple planar polishing on flat surfaces or symmetrical parts, SCARA or Cartesian robots offer the best balance of cost and performance. If surface contours or orientation shifts are frequent, a six-axis robot becomes essential. In environments requiring human-robot collaboration or rapid changeovers, cobots shine.

Ultimately, the best choice depends on your specific parts, required finish quality, budget, and operational constraints. Consider not only the robot’s cost but also its programming complexity, maintenance requirements, and compatibility with your existing workflow.

References

- Motion Controls Robotics – Range of Robot Cost – motioncontrolsrobotics.com

- Standard Bots – Robot Pricing Breakdown – standardbots.com

- EVS Robotics – Welding Robot Cost Guide – evsint.com

- JH Foster – SCARA vs. 6-Axis Robot Guide – jhfoster.com

- Robots Done Right – New vs. Used Robots – robotsdoneright.com

- Universal Robots Price Guide – standardbots.com

- FANUC CRX Pricing – standardbots.com

- KUKA vs. Competitors – standardbots.com