Newsletter

Request Our Latest Product Catalog

Get detailed specs, applications, and custom options for our robotic polishing, grinding, and deburring systems.

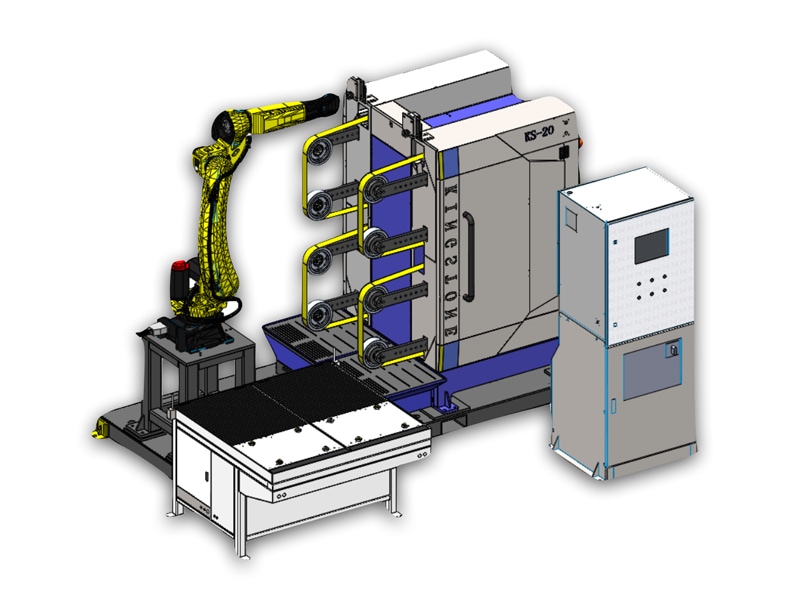

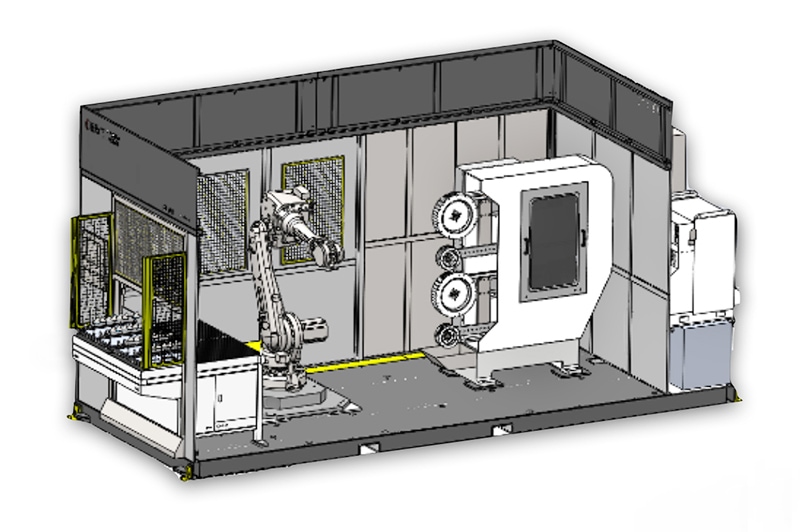

20-60KG Robot + Double belts sander + Dust proof safety room (optional for environmental protection)

20-60KG Robot + Double belts sander + Dust proof safety room (optional for environmental protection)

Our core technologies—automatic constant-pressure control, multifunctional fixtures, composite polishing wheels, and a proprietary software system—enable precise, consistent finishing on complex surfaces. Our solution fills a critical gap in the surface treatment industry.

From castings to bathroom hardware, we design robotic grinding and polishing systems tailored to your production needs.

Product

Copyright © 2025 Kingstone Robotics. All rights reserved.

Get detailed specs, applications, and custom options for our robotic polishing, grinding, and deburring systems.