Newsletter

Request Our Latest Product Catalog

Get detailed specs, applications, and custom options for our robotic polishing, grinding, and deburring systems.

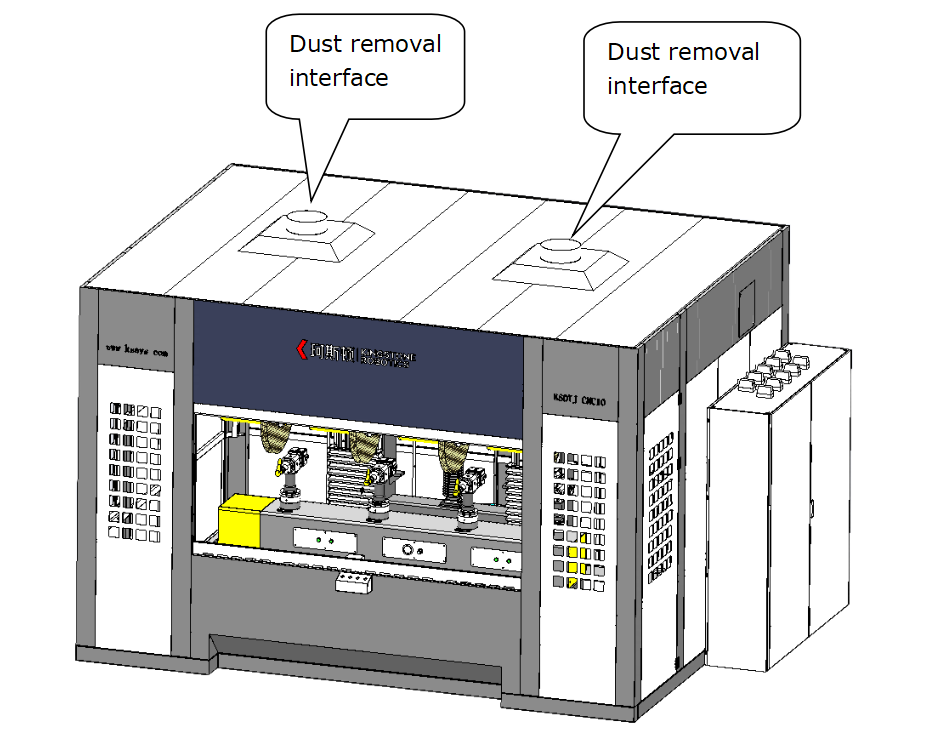

| Description | Unit | Specification |

|---|---|---|

| Table | ||

| Table size (LxW) | mm | 2760*395 |

| Height from ground (without fixture) | mm | 890 |

| Fixture rotating speed | rpm | 20 |

| Number of work stations | 4 | |

| Station size/Working Dia. (max) | mm | 350 |

| Number of Program Stores | set | ≥500 |

| Table Type | Movable – table moving by the screw rod/ball screw. | |

| Driven by servo motor. | ||

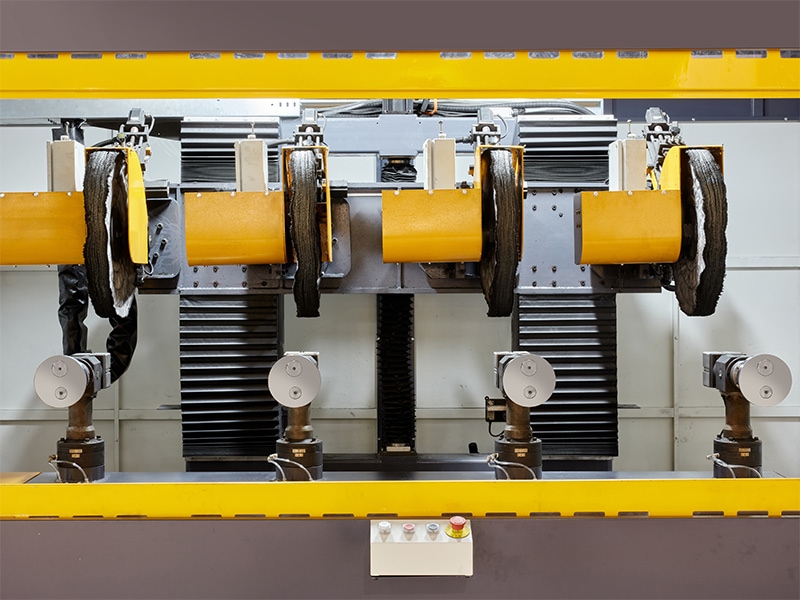

| Buffing/Polishing Heads | ||

| Number of head | 4 | |

| Main Spindle Polishing Motor | KW | 11.6 (4 nos. x 2.9 kw each) |

| Permissible Work Height | mm | 300 |

| Polishing wheel size (consumable) | mm | 600*60*10 mm |

| Polishing compound (consumable) | Type | Solid Wax |

| Polishing compound size (consumable) | mm | 350*60*10 mm |

| Polishing compound application | Automatic device for the solid compound feeding to the polishing wheel on a regular timing basis. | |

Our core technologies—automatic constant-pressure control, multifunctional fixtures, composite polishing wheels, and a proprietary software system—enable precise, consistent finishing on complex surfaces. Our solution fills a critical gap in the surface treatment industry.

From castings to bathroom hardware, we design robotic grinding and polishing systems tailored to your production needs.

Product

Copyright © 2025 Kingstone Robotics. All rights reserved.

Get detailed specs, applications, and custom options for our robotic polishing, grinding, and deburring systems.