Newsletter

Request Our Latest Product Catalog

Get detailed specs, applications, and custom options for our robotic polishing, grinding, and deburring systems.

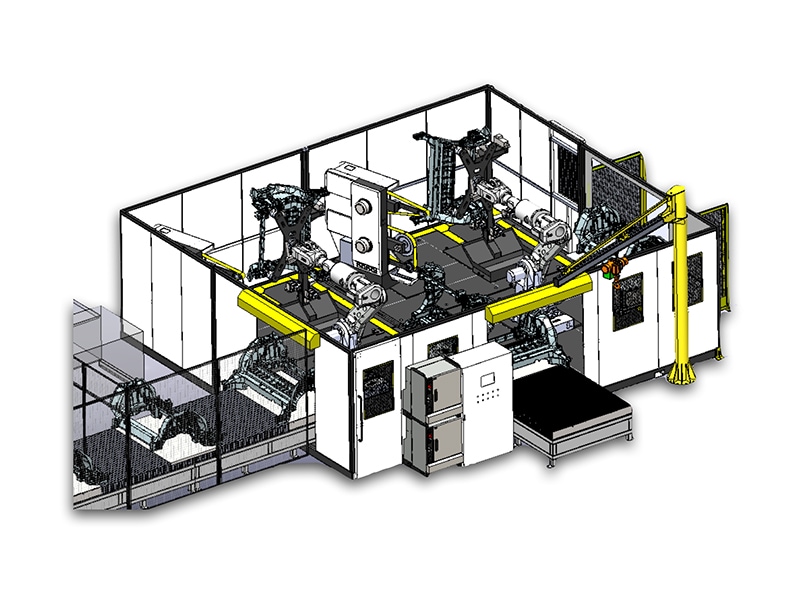

| Technical Parameter | |

|---|---|

| Robotic grinding cell | QTY |

| Robot Base | 1 |

| Grinding machine (3 belt each) | 2 |

| Sanding belt Qty | 6 |

| Sanding belt length | 4000mm |

| PLC flexible polishing system | 1 |

| Safety roon | 1 |

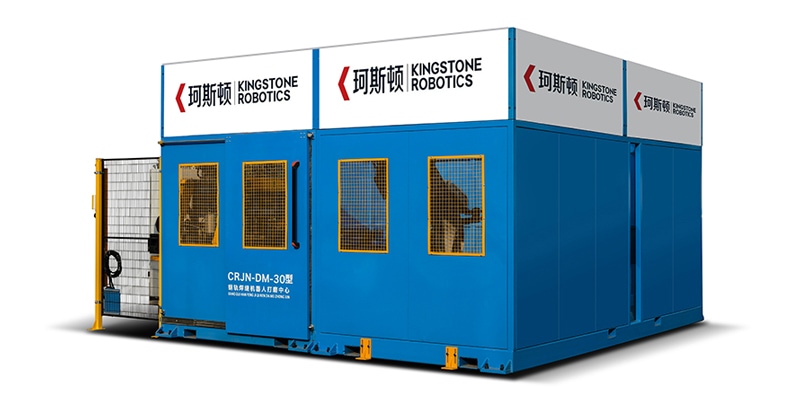

Our core technologies—automatic constant-pressure control, multifunctional fixtures, composite polishing wheels, and a proprietary software system—enable precise, consistent finishing on complex surfaces. Our solution fills a critical gap in the surface treatment industry.

From castings to bathroom hardware, we design robotic grinding and polishing systems tailored to your production needs.

Product

Copyright © 2025 Kingstone Robotics. All rights reserved.

Get detailed specs, applications, and custom options for our robotic polishing, grinding, and deburring systems.