Newsletter

Request Our Latest Product Catalog

Get detailed specs, applications, and custom options for our robotic polishing, grinding, and deburring systems.

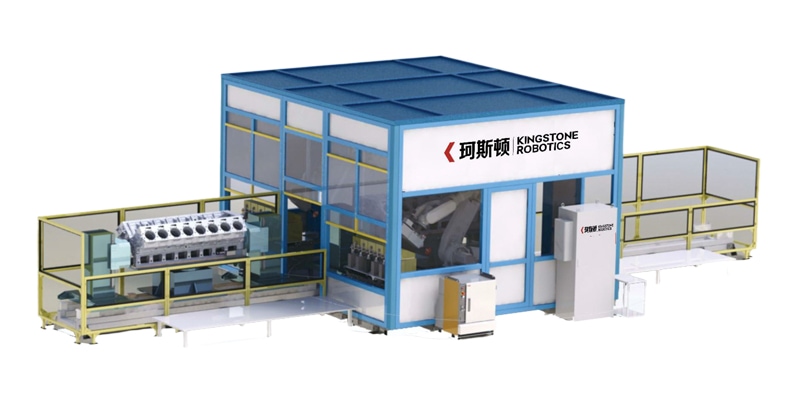

60-2300KG Robot + Deburring tool + Auto delivery table + Dustproof protective house(optional for environmental protection)Since each customer has different quality requirements for engine case, the processing solutions for same products is not fixed, so we will tailor-made large castings deburring system automation solutions.We provide turnkey projects, including fixture design, workpiece 3D drawing generation, equipment layout drawing, floor space 3D drawing and process schematic diagram.The robot deburring unit workstation is a standard/high-level configuration. The entire deburring process is completed automatically in this workstation at one time.

60-2300KG Robot + Deburring tool + Auto delivery table + Dustproof protective house(optional for environmental protection)Since each customer has different quality requirements for engine case, the processing solutions for same products is not fixed, so we will tailor-made large castings deburring system automation solutions.We provide turnkey projects, including fixture design, workpiece 3D drawing generation, equipment layout drawing, floor space 3D drawing and process schematic diagram.The robot deburring unit workstation is a standard/high-level configuration. The entire deburring process is completed automatically in this workstation at one time.

Our core technologies—automatic constant-pressure control, multifunctional fixtures, composite polishing wheels, and a proprietary software system—enable precise, consistent finishing on complex surfaces. Our solution fills a critical gap in the surface treatment industry.

From castings to bathroom hardware, we design robotic grinding and polishing systems tailored to your production needs.

Product

Copyright © 2025 Kingstone Robotics. All rights reserved.

Get detailed specs, applications, and custom options for our robotic polishing, grinding, and deburring systems.