Newsletter

Request Our Latest Product Catalog

Get detailed specs, applications, and custom options for our robotic polishing, grinding, and deburring systems.

| Parameter | Specification |

|---|---|

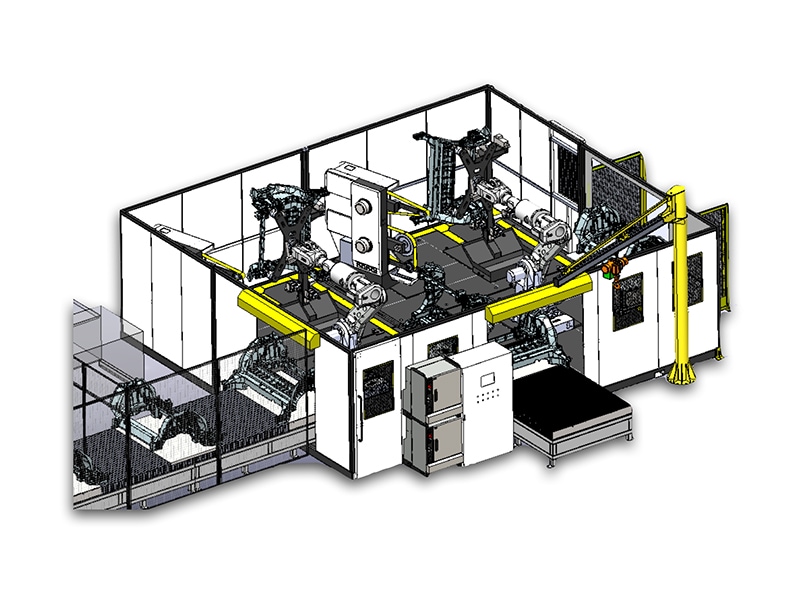

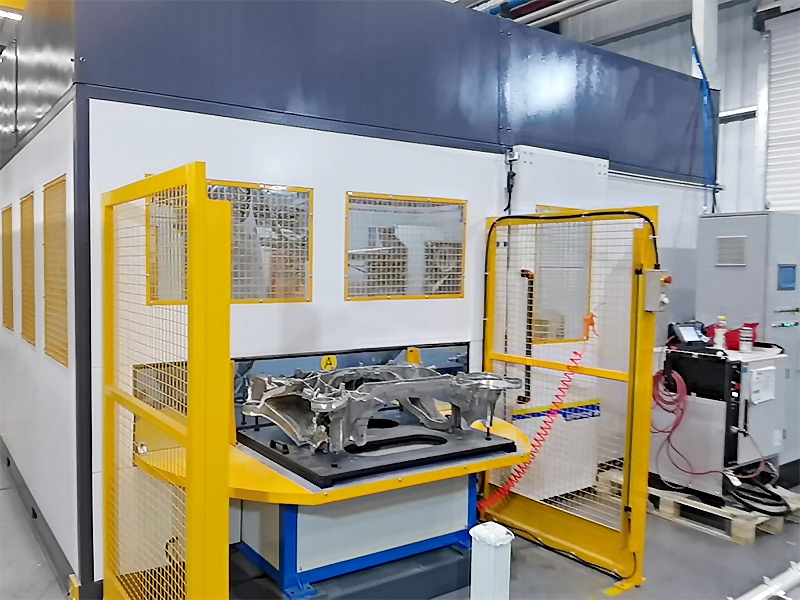

| Unit Type | Grinding and Polishing Unit |

| Robot Brand | FANUC, ABB, KUKA |

| Robot Weight | 60–2300kg |

| Sander Machine | 2–6 sets |

| Buffer Machine | 1–2 sets |

| PLC Brand | Siemens, Schneider |

| Polishing Consumables | Cloth wheel, sisal wheel, sand flap wheel |

| Grinding Consumables | Sand belt, foam wheel, sanding wheel, rubber wheel |

| Parameter | |

|---|---|

| Dimension | 4400x3400x2900mm |

| Machine Power | 25KW |

| Rated Voltage | 380V |

| Main Axis Motor Power | 4×2.9KW |

| Max.Diameter of Polishing Wheel | 600mm |

| Min.Diameter of Polishing Wheel | 350mm |

| Stoke of X-axis | 1100mm |

| Max.Speed of X-axis | 20m/min |

| Stoke of Y-axis | 900mm |

| Max.Speed of Y-axis | 20m/min |

| Stoke of z-axis | 700mm |

| Max.Speed of Z-axis | 20m/min |

| Stoke of A-axis | +90° |

| Max.Speed of A-axis | 30°/sec |

| Stoke of B-axis | 360° |

| Max.Speed of B-axis | 30°/sec |

| Stoke of C-axis | 360° |

| Max.Speed of C-axis | 30°/sec |

Our core technologies—automatic constant-pressure control, multifunctional fixtures, composite polishing wheels, and a proprietary software system—enable precise, consistent finishing on complex surfaces. Our solution fills a critical gap in the surface treatment industry.

From castings to bathroom hardware, we design robotic grinding and polishing systems tailored to your production needs.

Product

Copyright © 2025 Kingstone Robotics. All rights reserved.

Get detailed specs, applications, and custom options for our robotic polishing, grinding, and deburring systems.